The “Yuen Long Water Purification Facility”, which is being rebuilt and is expected to be put into operation in 2027, introduces “aerobic sewage treatment technology” for the first time, using “aerobic granule” sludge beads for cleaning, one-stop sewage treatment, reducing the space required for previous treatment , save the electricity needed to adjust the treatment environment, cooperate with the improvement of the design of incoming and outgoing water, and the co-anaerobic power generation technology of solar energy and sludge. The Drainage Services Department described: “Save more, produce more” can make the plant “energy neutral”, becoming the first self-sufficient sewage plant in Hong Kong for power generation.

Located in Yuen Long Industrial Estate, the Yuen Long Sewage Treatment Plant covering an area of 8.6 hectares has been in operation for more than 30 years. The original site will be rebuilt at the end of 2020, and the level of sewage treatment will be upgraded from the second level to the third level, which can reduce the amount of purified water by 50% Residual organic matter also increased the sewage treatment capacity from 70,000 cubic meters per day to 100,000 cubic meters, becoming the “Yuen Long Water Purification Facility” and applying “aerobic granular sludge technology” for the first time.

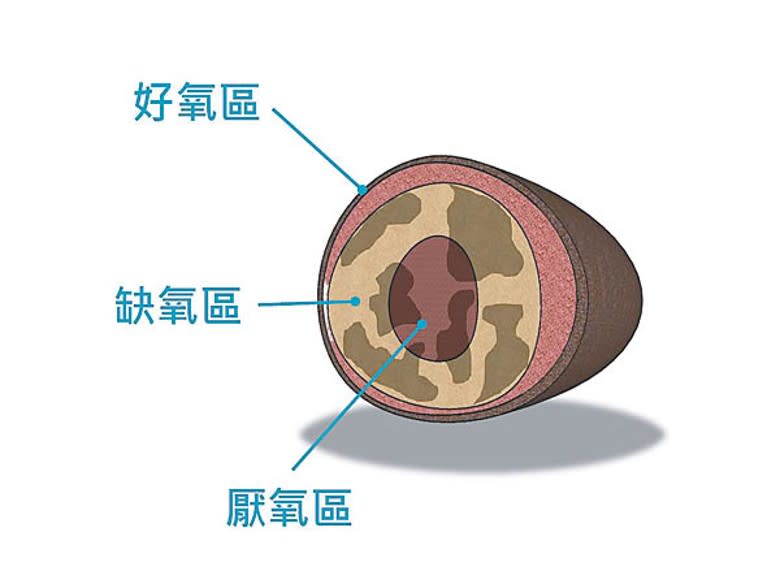

Chen Yunyin, engineer of the Drainage Services Department, said that traditional sewage treatment plants need to separate the aerobic zone, anoxic zone and anaerobic zone. The microorganisms in the oxygen zone will remove the ammonia that poisons the fish, which requires a large space, and also uses energy to start the air pump for a long time to maintain a suitable living environment for microorganisms.

Granules for 3 concentrations of dissolved oxygen

The new technology only provides three concentrations of dissolved oxygen through aerobic granular sludge beads with a diameter of only 0.2 to 0.4 mm. Gas” and “rapid sedimentation” in 3 steps, microbial retention and water purification, while removing organic matter, ammonia, nitrogen, phosphorus and other pollutants.

Chen Yunyin said that aerobic granular sludge beads are conducive to oxygen penetration, can control the amount of oxygen more accurately, reduce the power consumption of mechanical equipment such as agitators and circulation pumps during the aeration (airing) stage, and their volume is relatively small. In the past, the sludge beads were large and the sedimentation speed was faster, which might treat sewage faster and reduce land demand. The aerobic granular sludge technology is expected to save regarding 20% of electricity consumption compared with the past.

The Drainage Services Department has also installed a pump station at the outfall of the factory building, which will only be activated when the river is in high tide, and the hydraulic pressure will be applied to discharge the water, reducing the pumping height of untreated sewage entering the sewage treatment plant and saving energy. Chen Yunyin pointed out that the water pump only needs to be started once a year. Compared with not adding a water outlet pump room at the water outlet location, the factory can save regarding 16% of electricity consumption compared to the past.

At the same time, co-anaerobic technology is installed in the plant, using microorganisms in an oxygen-deficient environment to digest the sludge formed during the sewage treatment process and generate biogas for power generation. The Drainage Services Department expects to produce regarding 3.5 million kilowatt-hours of electricity per year in the initial stage of operation, which is enough to meet regarding 30% of the electricity demand of the facility. It will also receive regarding 125 tons of anaerobic digestion of sludge from other sewage plants when the usage is not at its peak. It is estimated that it can generate an additional 8.2 million kilowatt-hours of electricity per year, which is enough to meet the remaining 50% of the electricity demand of the facility. A total of 11.7 million kilowatt-hours of electricity is equivalent to the annual electricity consumption of regarding 3,545 three-person households.

5000 photovoltaic panels top government facilities

The water purification facility is also equipped with a solar power generation system consisting of more than 5,000 solar photovoltaic panels, which will be the largest solar power generation facility in Hong Kong government facilities. It is estimated that the annual power generation will reach 2.3 million kilowatt-hours, which is enough for regarding 700 three-person households to use throughout the year .

It’s just that following the rebuilding, the cost of sewage treatment in the facility has risen from 2.1 yuan per cubic meter to 6.1 yuan. Chen Yunyin explained that since the facility was upgraded to a third-level sewage facility, filtration and ultraviolet light disinfection procedures were added; while the cost of sewage treatment is difficult to compare, aerobic The sludge beads are still patented, and the cost is “less expensive” than before. However, the sludge beads can be used continuously and will not be consumed until many years later.