When we reread some test from the sixties, it is not uncommon for the author to point out a noticeable improvement in behavior when the tested model goes from bias to radial tires. Of all Michelin’s innovations, the ‘Radial’ is, without a doubt, one of the ones that has revolutionized the landscape the most. This story starts in the thirties of the last century. The car evolves very quickly. The engines increase their power at the same time that the benefits increase. And front-wheel drive appears as an alternative to propulsion. And motorists no longer just want to get from one place to another, they want to do it faster and safer.

tires. Michelin develops instruments that allow the performance of its tires to be measured while in motion. This is how it begins to be understood what happens inside a tire when the car moves. The better knowledge and the increase in performance lead the Clermont Ferrand engineers to rethink the structure of the tires, convinced that adding a more resistant material to those used until then (rubber and textile) would improve the performance of the tires. tires.

A first step, the Metalic

And since nothing is more resistant than metal, they decide to study its interaction with rubber and textile reinforcements and, following six years of work, manage to combine them. Michelin thus manufactures layers of drawn steel wires, very resistant and at the same time very elastic. This discovery opens up new perspectives and allows, in 1937, to develop the first steel body for trucks: the ‘Metalic’. Two years later World War II breaks out, and the investigations continue, but now hidden from the eyes of the German occupier.

The commitment of Marius Mignol

Marius Mignol is one of the engineers who has worked on the ‘Radial’ tire project, and he is not satisfied with the goals achieved, he wants to go further and is convinced that the path taken can serve to achieve further progress. It is in the year 1940 when the project starts with the construction of a prototype that they baptize as ‘La came’, something like ‘fly cage’, which is what, due to its appearance, this Radial casing reminds .

The idea seems simple. Before, to make a tire, different layers of products (textiles and rubber) were stacked on top of each other. In the case of truck tires, due to the need to offer greater resistance, they were up to twenty layers. And the moment the tire started moving, on the road, those capabans rubbed once morest each other. This resulted in wear and heating, thus increasing the risk of blowout and, as would be seen later, energy consumption.

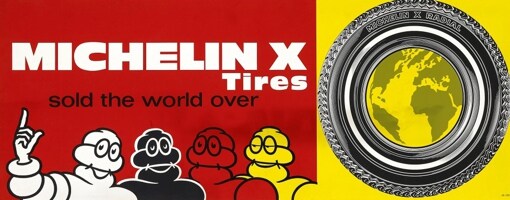

So the idea of the Radial was to separate the work of the tire’s sidewalls from the tread. For this, a carcass that is as simple as possible is conceived, made with small parallel threads all oriented towards the center of the tire, hence the name ‘Radial’ for the carcass. This carcass will be surrounded by metallic reinforcing layers oriented at 45 degrees, one in one direction and one in the other, which forms an ‘X’, which would be the origin of the tire’s commercial name.

These ‘X’s, when they cover the casing threads, form a multitude of small triangle-shaped figures, non-deformable and that provide the qualities in terms of behavior of this type of tire. It was quite a revolution.

The ‘X’ is patented

The war ends and in 1946, Michelin patents the Radial tire, which allows more kilometers to be covered with better safety conditions, and consuming less energy. It was presented at the 1949 Paris Salon under the name ‘Michelin X’, a tire that left its competitors behind.

Drivers discover the benefits brought by this innovation, actually a break with the past in every respect. The main advance was in safety, because it grabbed much more, especially in the curves. And then the duration: it allowed to multiply by three or four times the mileage. Without forgetting that, by reducing the heating of the tire inside, the energy demand was reduced. For example, for an average French car from the 1950s, such as a 1955 Peugeot 403, one liter was saved for every hundred kilometers travelled. This meant for a car that would travel 15,000 kilometers per year, 150 liters of savings, a very important figure.

archyde news

It was undoubtedly a revolution, but it had to be made known both in France and in the rest of the world. In this regard, it is very important to underline the role of François Michelin, grandson of the firm’s founder, and a key figure as its president (we are talking regarding the 1950s) in imposing the new tire. To publicize its Radial, Michelin uses various means such as direct and competition. And there is also an emblematic model from the 50s that will contribute to the notoriety of the ‘X’ tire, we are talking regarding the Citroën DS.

Let’s talk regarding . At the 1952 Paris Salon the famous mascot, the ‘Bibendum’ gets married! This symbolizes the ‘marriage’ between steel and textile, characteristic of radial technology. Another example. Since 1935, following the famous flywheel crisis, Citroën has belonged to Michelin. This allows the firm from Clermont Ferrand to equip the 1955 DS with radial tires at the factory. What better platform than a model that advanced the future to associate itself with the image of the most advanced tire? And the competition, which allowed Michelin to get ahead of its rivals. The victory in its class of the Lancia Aurelia in the 1951 edition of the 24 Hours of Le Mans, makes teams and drivers begin to be interested in the radial tire of the French house.

In this aspect, in the sixties, there is the figure of a Michelin engineer named Pierre Dupasquier, convinced of the possibilities of radial tires in competition and also for high-performance road cars: his good relations with Enzo Ferrari will lead to that Il Commendatore entrusted him with the development of specific radial tires for the fantastic 1968 Daytona. And this would also pave the way for the radial to Formula 1, the greatest exponent of motorsport. But that is another story that I will tell you.

A before and following in Michelin

So back to our story today. Radial technology is gradually applied to other types of tires: trucks (1952); civil engineering (1959) and agricultural machinery (1978), airplanes (1981) and motorcycles (1987). The X not only changed many things in the automobile field but also in the firm that created it. Between 1947 and the end of the 1970s, Michelin opened some forty plants in France, Europe and the United States. In 1976, the Ford Motor Company decided to equip the Lincoln Continental Mark III with X tires, with Michelin becoming the official supplier. In 1978, it is the consecration of the Radial in the United States. The Americans give Michelin the Sperry Award, which recognizes the Radial as a key technological advance of the 20th century. Actually, that X is the showcase of a maverick brand from a technological point of view, which is always looking for something different, something better.