2024-03-17 23:04:36

Formerly reserved for professionals and enthusiasts with advanced technical knowledge, the world of 3D printing has become more and more accessible in recent years. Technological advances and progressions from a software point of view have lowered costs and opened the door to a wide audience to explore this world of additive manufacturing. However, such a large market, often filled with technical terms and vague marketing claims, can be confusing for beginners. It is to help demystify the 3D printing market and help simplify the process of choosing your first 3D printer that we are sharing this guide. Discover our advice to make an informed decision and know which 3D printer to choose!

3D printing, a set of different technologies and processes

FDM, FFF, MSLA, SLA, DLP and many other technical terms and abbreviations will probably be familiar to you if you have already started your 3D printer search. But what do all these terms mean? Regardless of the technology used, 3D printing, also known as additive manufacturing, brings digital 3D models to life by building objects layer by layer. This allows for the creation of all kinds of objects, from custom figurines and functional prototypes to architectural models and even medical prosthetics.

3D printing allows you to create many types of objects like this architectural model

Although a large number of 3D printing processes exist, two technologies in particular are suitable for the consumer market thanks to their ease of use and cost of entry: FDM (also called FFF or fused deposition in French) and resin printing (particularly MSLA, Masked Stereolithography).

Filament 3D printing: a “simple” choice for a first 3D printer

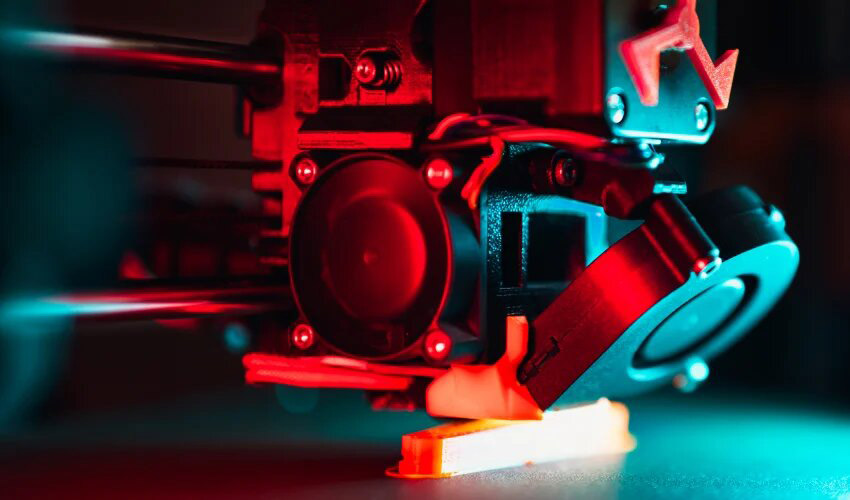

FDM or FFF printers are the most popular in the collective imagination; most people think of this technology when we talk regarding 3D printing due to its boom in popularity generated by the Reprap project and its accessibility. These are 3D printers that use spools of filament: they work similarly to a hot glue gun, extruding a filament of molten plastic through a nozzle to build the object layer by layer.

The advantages that make FDM a good choice for a first 3D printer:

- Affordability : FDM printers are generally the most economical option, making them ideal for beginners. Machines are available from around €200 for the entry level and materials from around €16 to €25/kg for the most basic.

- Material compatibility : FDM printers (depending on their technical capabilities) can work with various materials such as PLA, ABS and even composites, allowing a large number of varied applications.

- Ease of use : FDM printers are generally intuitive and simple to learn, with readily available filament and minimal maintenance requirements.

FDM 3D printing uses spools of filament to produce parts

The limits of FDM that will make you reconsider your choice:

- Print quality : Compared to resin printing, FDM prints have a lower resolution and individual layers are discernible with the naked eye.

- Print speed : FDM printing can be slower than resin printing, especially for larger objects or the production of a large number of parts simultaneously.

To discover how the 3D printing process by filament deposition works in more detail, discover our dedicated guide.

Resin 3D printing: exceptional quality at the cost of a tedious process

Resin printers, increasingly popular thanks to technological advances and their decreasing price, particularly for MSLA technology, use a UV light source to cure liquid resin layer by layer, creating the desired object.

Resin printing offers several advantages:

- Superior details and finish : Resin prints feature smoother surfaces and finer details compared to FDM.

- Ifaster printing : Resin printing can be significantly faster than FDM, especially for large, complex designs.

Resin 3D printing uses a tank in which the material is in liquid form (photo credits: 3Dnatives)

However, resin printing also has disadvantages:

- Post treatment : Unlike FDM, resin requires post-processing for all produced objects. This manual work, which can be assisted by machines, necessarily includes cleaning and post-polymerization as well as the removal of supports in the majority of cases.

- Limited print volume : resin 3D printers generally have a small platen with a reduced printing height compared to FDM. It is therefore complicated to produce large parts.

- Security : handling resin requires caution as it can be irritating and harmful. Proper ventilation and protective equipment (including gloves) are essential when using a resin printer.

- Limited material selection : Resin printers have fewer material options compared to FDM.

- Higher cost: Resin printers generally cost more than FDM printers, both in terms of the initial purchase and ongoing costs of resin and other consumables (although MSLA printers are available at similar prices to FDM printers, it takes purchase post-processing equipment).

Resin 3D printing brings together several technologies, the most accessible being MSLA. Discover the similarities and differences between SLA, DLP and MSLA through our explanatory guide.

Identify your needs to better choose your first 3D printer

There is no one perfect 3D printer for all applications, they all have strengths and drawbacks that make them more or less relevant for your use.

Before buying a printer, it is important to think regarding the projects you want to carry out to identify your needs

When choosing your first 3D printer, here are the key factors to consider:

- Volume d’impression : What is the maximum size of the objects you plan to print? Printers come with varying platen sizes and print heights, it is important to choose a print volume corresponding to the planned projects (assembly always remains a possibility for bulky parts).

- Material Compatibility : consider the materials you want to work with for your projects. For the filament, this factor will be mainly determined by the maximum platen and extrusion temperatures as well as the presence of a closed and heated enclosure.

- Ease of use : are you comfortable with technology and DIY? A proprietary printer and an ecosystem can restrict an advanced user wishing to experiment but are on the contrary practical for a beginner requiring a plug & play solution.

- Print speed : How long are you willing to wait for your prints?

- Reliability and durability : How important is consistent performance and long-term use? Are you ready to do regular maintenance on your machine?

- Software used : Choose a printer compatible with slicing software that you are comfortable with or willing to learn.

- Budget : the price of the machine itself is an important factor but also the materials (especially in the case of a proprietary solution), consumables and associated tools.

By carefully considering these factors, you can more easily navigate through the various options and choose a 3D printer that fits your specific needs and projects. Remember, there is no one “best” printer for everyone. The ideal choice depends on your individual needs and printing goals. With this guide as a starting point, you will be well on your way to discovering the world of 3D printing!

Have you already chosen a 3D printer? Share your opinion in the comments to the article. Find all our videos on our channel YouTube or follow us on Facebook or Twitter !

Receive post notifications Unsubscribe from notifications

1710724509

#printer #choose #starting