2023-04-26 22:05:00

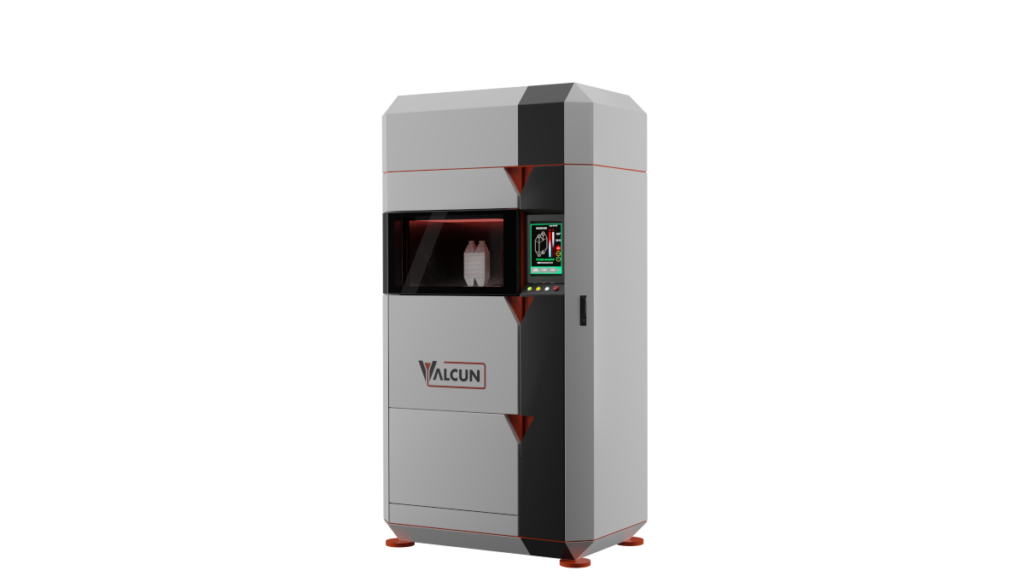

The Flemish startup Valcun is starting the pre-sale of the 3D metal printer for aluminum, Minerva. They will record the first pre-orders at Rapid-TCT in Chicago. Recently at the AMUG conference in Chicago, Valcun received a lot of positive feedback on some of the aluminum parts on display.

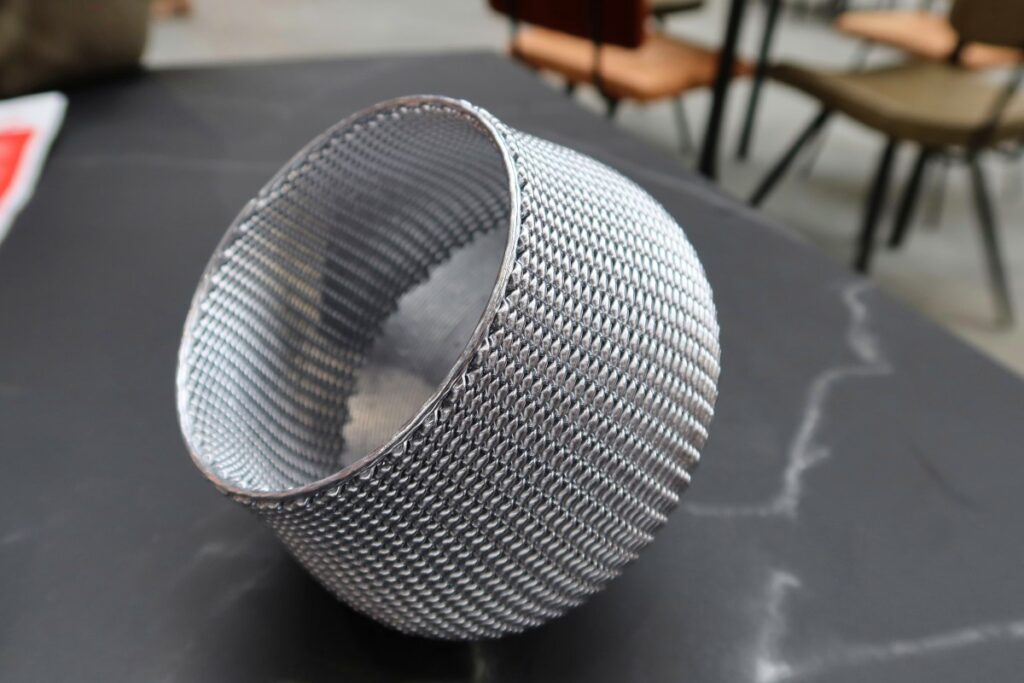

When Jonas Galle, founder and CEO of Valcun, introduces one of the components, it quickly becomes clear why it has received an enthusiastic response. Valcun 3D prints aluminum with an overhang of up to 70 degrees without the need for a support structure. “You can easily remove the part from the building plate, without a milling or EDM machine. And we think that with 70 degrees we are not yet at the limit.” The Belgian startup not only received positive feedback at AMUG last month, but was also included on a SmarTech report highlighting emerging and promising AM technologies. “We are on the list of companies to keep an eye on. That is good, because now more people from the sector know us,” says Jonas Galle.

Molton Metal Deposition: FFF printing with aluminum wire

ESA has ValCUN demonstrate printing in space

Valcun’s small team, supported by a number of internationally experienced AM experts, develops the Molten Metal Deposition technology. The process is similar to FFF, but with aluminum as the feedstock that passes through the extruder. The feedstock is aluminum wire (currently the aluminum 4000 series, for aluminum 6000 the parameters are being developed and will be released together with the first machine). Recently, the European space agency ESA also discovered the Belgian startup. “ESA has approved a project to demonstrate the first step towards 3D printing in space,” explains Jonas Galle. He has no doubts that the Minerva 3D printer can print aluminum parts in an environment without gravity. In theory, this is even the ideal environment. “Since there is no oxygen, no oxidation might occur. Also gravity works once morest the process. Microgravity as in space would then only be an advantage. We now have to demonstrate that we achieve the same quality, regardless of the position of the 3D printer.”

Few competitors

The Molten Metal Deposition Technology is unique in the AM industry. In fact, Valcun had one serious competitor in development so far: Xerox. That took over the technology from the American Vader Systems a few years ago. Vader also printed aluminum, albeit with a different technique. Late last year, however, Xerox – informally – pulled the plug on the AM project. Another possible competitor might be the German machine builder Grob, who first showed the machine for the Liquid Metal Printing concept on Formnext. Grob also 3D prints with aluminum. However, the footprint of the Minerva 3D metal printer is many times smaller than that of the German one for the same building volume. “Just like the price tag,” says Jonas Galle.

On the left the Valcun Minerva aluminum printer; in the middle the print head and on the right a product example.

Capital round postponed

Actually, a new investment round was planned for this year. Jonas Galle: “We wanted to do a capital round but we are trying to postpone it. We first want to market the machine with R&D and scientific researchers as focus groups. With their feedback, we can make the final production machine better and we are in a stronger position towards potential investors.” The first version for which the order books will open soon will be a fully open system, so that users have access to all parameter settings as well as materials. “We are looking for users who want to help optimize the machine,” says Jonas Galle. The next generation will then be released for wider market introduction. This will then be a more industry-adapted version. Because the company is gradually entering the market, it is looking for a business developer, among others.

If we succeed in printing aluminum 6061, a stronger material, we will be the game changer in the market

Industrial applications

With this industrial 3D metal printer, Valcun focuses on manufacturing companies that want to have aluminum parts where the combination of AM and aluminum can provide economic added value. Think, for example, of semi-finished products, heat exchangers, catalysts and other complex parts. Ease of use – both in terms of printer and material availability – and speed and low cost are the features the team still holds on to. Because the parts can be easily removed from the construction site thanks to the unique AM process, the Minerva 3D metal printer can be automated quite easily from the start. A final advantage that Jonas Galle points out is the low energy consumption. A standard 230V socket is sufficient. “If we succeed in printing aluminum 6061, a stronger material, we will be the game changer in the market.”

Next generation in the pipeline

The development certainly does not stop there. The roadmap includes 3D printing with aluminum chips from machining and the development of a print head that is placed on a robot arm for larger parts. Valcun is one of the parties in the 3DOP project that was officially presented last year during Formnext at the Brainport Development stand. 35 partners from eight European countries are participating in this. The Belgian 3D printer manufacturer participates, among other things, in the work package optimization of production through AM. The project should provide building blocks for the next generation Valcun 3D metal printer. This should make series production with additive manufacturing substantially cheaper, without compromising on quality and industrialization.

Photo: Johan Galle, co-founder and CEO of Valcun, together with Jan de Pauw, co-founder and CTO (photo: Valcun)

URL Copied

1682560115

#Valcun #launches #aluminum #printer #Minerva