Silicon Breakthrough: Integrated Lasers on Chips Poised to revolutionize Data Centers

By Tech News Desk

Published: April 15, 2025

For decades, silicon chips have been the backbone of modern dialogue, powering everything from smartphones to supercomputers. Now, a groundbreaking advancement in silicon photonics promises to further revolutionize how we process and transmit information. Researchers from the U.S.and Europe have achieved a milestone: fabricating miniaturized lasers directly onto silicon wafers. This growth, detailed in a study in Nature, could lead to faster, more efficient, and more cost-effective data transmission.

The potential impact on data centers, in particular, is enormous. Photons, or light particles, offer significant advantages over electrons in transmitting data. Thay are faster, have a greater data capacity, and experience lower energy losses. This translates to increased processing speeds and reduced energy consumption, critical factors for the massive server farms that power the internet.

traditionally, integrating lasers onto silicon chips has been a major hurdle. The conventional approach involves attaching a separate laser light source to the chip. Though, this method introduces inefficiencies due to mismatches during autonomous manufacturing. As the study highlights, “the resulting device operates more slowly than a chip with an integrated light source as of the small but significant mismatches that arise due to being manufactured independently. Separately manufacturing and attaching the lasers is also more expensive.”

The new research tackles this problem head-on by “growing” the laser directly on the silicon chip. This integrated approach promises not only improved performance but also greater scalability, paving the way for mass production.

A typical silicon chip comprises four key components: a source (electrons or photons), waveguides, modulators, and photodetectors. In a photonic chip, the laser serves as the light source, a component that has been notably challenging to integrate directly onto silicon.

- Laser (Light source): Generates the photons that carry the data.

- Waveguides: Act as pathways for the photons, analogous to wires for electrons.

- Modulators: Encode information onto the light by varying its intensity, wavelength, or phase. They also decode information from incoming light signals.

- Photodetectors: Convert the light signals back into electrical signals for processing.

Lasers function thru a process called stimulated emission. “Here,an electron in a higher energy level is ‘kicked’ by an incoming photon to lose some energy and drop to a lower energy level. This energy lost is in the form of another photon whose energy matches that of the incident photon. When this process occurs repeatedly, the population of electrons generates a coherent beam of light. This is a laser.”

Many lasers are made from semiconductor materials like gallium arsenide, known for their direct band gap. This property allows electrons to efficiently emit photons when transitioning between energy levels. However, integrating gallium arsenide with silicon presents a significant challenge because of their differing atomic structures.The study notes that “When gallium arsenide is grown layer by layer on silicon, the mismatch in the crystal structure of the materials causes imperfections where the atomic patterns don’t line up properly.” These imperfections can lead to energy loss as heat, reducing the laser’s efficiency.

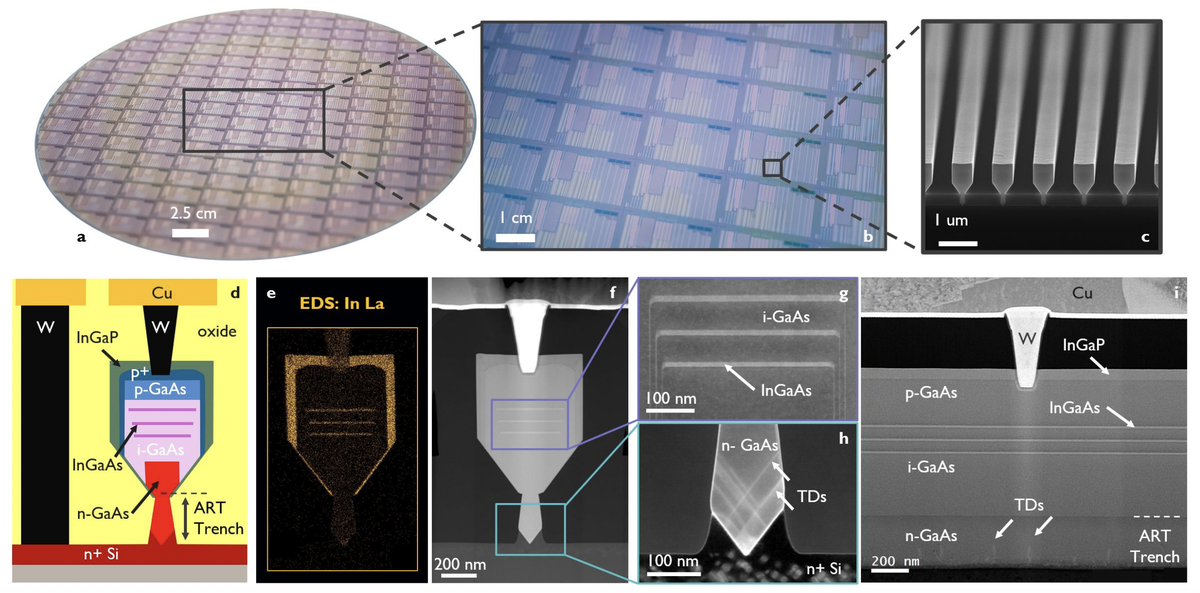

The research team overcame these challenges by employing a novel approach. They created a chip with a silicon wafer base,nanometer-sized ridges for photon travel,and a dedicated region for photon production. The concept of using ridges was inspired by a 2007 study from AmberWave Systems Corp., which demonstrated that depositing gallium arsenide in narrow, deep trenches surrounded by an insulating material could trap defects and prevent them from interfering with laser operation.

The researchers carved these nanometer-wide ridges into a 300-mm silicon wafer and used silicon dioxide as the insulating material. This effectively confined defects to the bottom of the trenches, allowing for the growth of a defect-free gallium arsenide crystal above. Subsequently,they deposited three layers of indium gallium arsenide,each only a few atoms thick,to function as the laser. a layer of indium gallium phosphide was added for protection.

| Photo Credit: arXiv:2309.04473v1

This innovative design allowed the researchers to successfully embed 300 functional lasers on a single 300-mm silicon wafer, a standard size in the semiconductor industry. This compatibility with existing manufacturing processes is a key advantage.

The resulting laser emits light at a wavelength of 1,020 nm, ideal for short-range data transmission between computer chips. “Thus the researchers expect their chip could lead to a substantial improvement in computing performance and reduce energy consumption in data centers.” The laser’s low threshold current of 5 mA,comparable to an LED in a computer mouse,and its output of around 1 mW,further underscore its efficiency.

While the laser demonstrated continuous operation for 500 hours at room temperature (25° C), its efficiency decreased at higher temperatures (around 55°C). Recent advances in optical silicon chips have achieved continuous operation at temperatures up to 120°C, indicating that further research is needed to enhance the stability of these semiconductor lasers.

Despite these challenges, this breakthrough marks a significant step forward in silicon photonics. “In sum, the photonic silicon chip is novel because it’s the first demonstration of a fully monolithic laser diode on a silicon wafer of this size. The team’s process is also scalable and cost-effective.”

The ability to integrate lasers directly onto silicon chips using existing manufacturing processes opens up exciting possibilities for the future of computing. This technology has the potential to transform data centers, enabling faster processing speeds, reduced energy consumption, and more efficient data transmission. As research and development continue,we can expect to see even more innovative applications of silicon photonics in the years to come.

The implications of this technology extend beyond just data centers. consider these potential applications:

| Application | Benefit |

|---|---|

| High-Performance Computing | Faster data transfer between processors, enabling more complex simulations and calculations. |

| Advanced Sensors | Improved accuracy and sensitivity in environmental monitoring, medical diagnostics, and industrial automation. |

| Quantum Computing | Enabling new architectures and improved performance for quantum computers. |

| Telecommunications | Higher bandwidth and faster data transmission speeds for internet and mobile networks. |

| Automotive Industry | Advanced driver-assistance systems (ADAS) and self-driving cars with faster and more reliable sensor data processing. |

While this integrated laser technology offers tremendous promise, there are still challenges to overcome. Improving the laser’s stability and efficiency at higher temperatures is crucial for real-world applications. Further research is also needed to optimize the manufacturing process and reduce costs.

However, the potential rewards are significant.Widespread adoption of silicon photonics could lead to a new era of computing, characterized by increased performance, reduced energy consumption, and a wide range of innovative applications. As the technology matures, it is likely to play an increasingly significant role in shaping the future of our digital world.