2023-05-25 18:59:01

Semiconductors: what are these little parts that are wreaking havoc in the auto industry

When the World Health Organization – WHO decreed a global pandemic, due to COVID-19, in March 2020, the whole world stopped and one of the most affected industries was (and still is) the automobile industry. The result was a significant reduction in the supply of semiconductors, these essential components for all segments, which resulted in a drop in industrial production in countries around the world.

The lack of these components has been compromising the global production of vehicles at automakers

With the gradual resumption of industrial activities, semiconductors were directed mainly to computer, smartphone and communication systems companies. The automotive sector consumes 11% of all semiconductors produced in the world and a study commissioned by the Association of the Automotive Industry of Germany – VDA, released in February this year, showed that the lack of these components can result in a global drop of 20% in production. until the year 2026, which corresponds to around 18 million vehicles.

The automobile industry was very affected by the sanitary measures in the Pandemic

Semiconductors began to be inserted in the automobile industry in the 1960s, but their use was related to limited applications, such as electronic ignition, for example. In the following years, there was an increase in the use of these components in motor vehicles, thanks to technological advances and the demand for more sophisticated electronic resources present in cars. It was from the 1980s onwards that semiconductors began to be widely used in engine control systems, anti-lock brakes (ABS), electronic fuel injection and traction control. These systems rely on electronic circuits to process information and make real-time decisions to improve vehicle efficiency, performance and safety.

In recent years, with the advancement of automotive technology, the use of semiconductors has become even more essential, as current models are equipped with a variety of advanced electronic features such as entertainment and navigation systems, driver assistance, parking sensors, rear view cameras, communication and connectivity systems, among others. All of these features depend on semiconductors for their proper functioning.

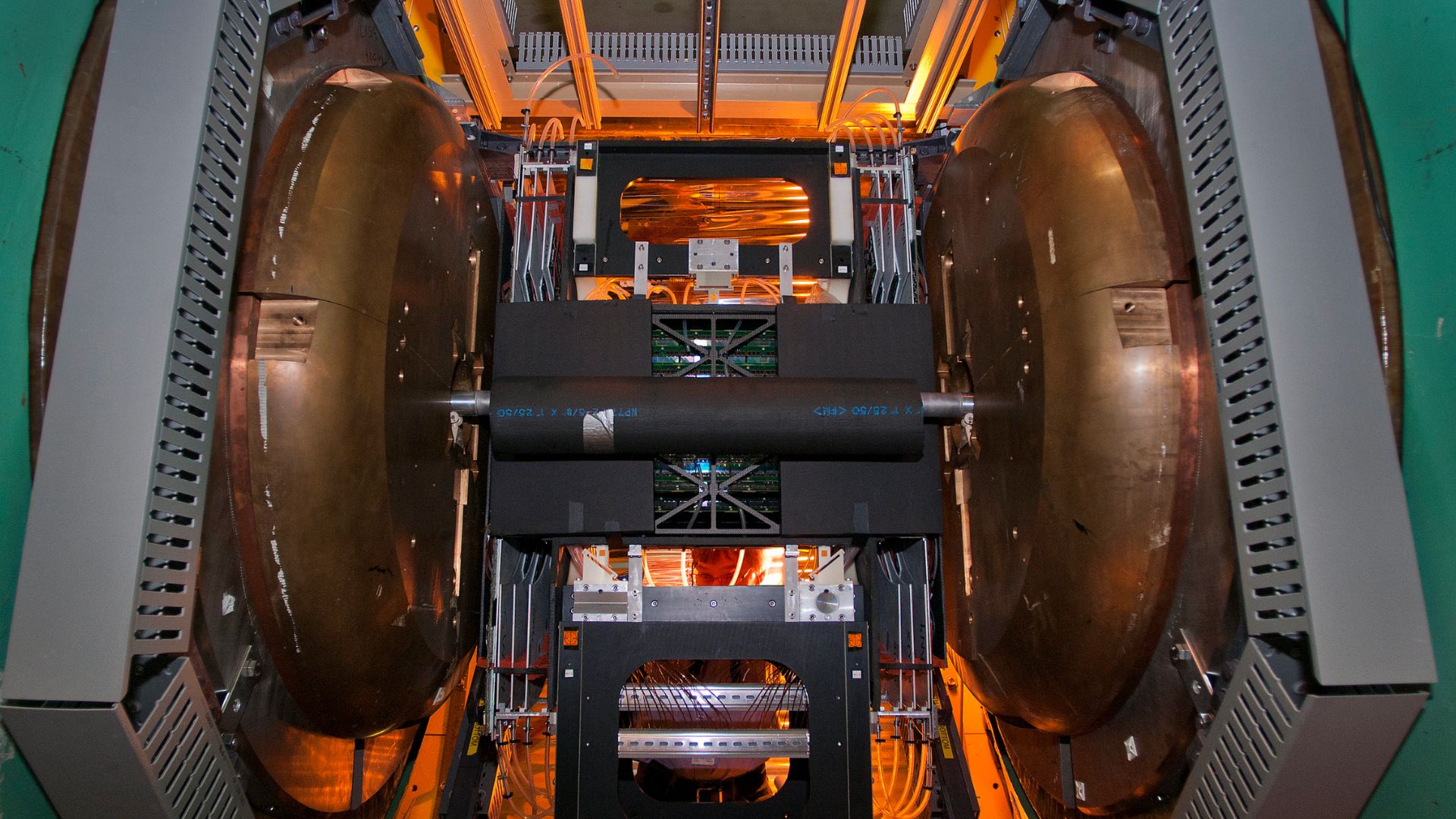

Semiconductors are essential for the perfect functioning of vehicles

It is also worth mentioning that, with the development of electric and autonomous vehicles, semiconductors are even more, of extreme need in the automotive industry. Electric propulsion, battery management, driver assistance, and autonomous perception and decision-making systems are examples of functionality where semiconductors are widely used.

Brazilian automakers have been reducing vehicle production and, in some cases, even temporarily paralyzing their operations, due to the lack of these electronic components. This results in delays in new vehicle deliveries and also a significant impact on the auto parts supply chain. Brazil’s dependence on semiconductor imports also contributes to the situation, as the country does not have a significant production of semiconductors, depending on foreign suppliers, mainly from Asian countries.

The Brazilian government has sought measures to mitigate the impacts of semiconductor shortages on the automotive industry, with tax incentives and programs to stimulate local semiconductor production, but building a national semiconductor industry takes time and requires significant investments in infrastructure and research. .

For DPK’s Product Manager, Antonio Marcos Pereira, the entire chain involved in the automobile industry has been suffering from the shortage of semiconductors and is being forced to reinvent itself. “The lack of components affected not only the automakers, but everyone involved in the process. The market found itself obliged to reinvent itself, as semiconductors are currently responsible for the proper functioning of almost all the resources offered by vehicles. The Brazilian market is very dependent on components that are produced in other countries, so we have to think regarding encouraging local companies to reduce this dependence, but it is clear that this is a medium and long-term solution,” said Pereira.

About DPK

Specialized in automotive distribution in Brazil, DPK has been in the market since 1987, with fifteen branches across the country with an advanced product distribution system. With its headquarters in Campinas and always attentive to the modernization of the market and the customer’s demand for more dynamic services and assistance, DPK created KDaPeça, a complete and simple-to-use electronic catalogue, through which it is possible to shop online, check the stock, make personalized budgets and compare products, 24 hours a day.

Learn more at: Link

1685051497

#Semiconductors #auto #industry