2024-02-27 23:05:10

The use of 3D bioprinting in the field of regenerative medicine is constantly growing. More and more companies are developing their own additive manufacturing solutions to create organs and tissues adapted to the needs of each patient. With this idea in mind, biotechnology company Vital3D offers advanced solutions for medical research, drug discovery and regenerative medicine. The goal? Integrate cutting-edge 3D bioprinting technologies (such as two-photon polymerization) to shape the future of medicine through personalized treatment for patients. We spoke with the company’s CEO to learn more regarding its manufacturing systems and his view on the current state of 3D printing in the healthcare field.

3DN: Could you introduce yourself and tell us regarding your relationship with 3D printing?

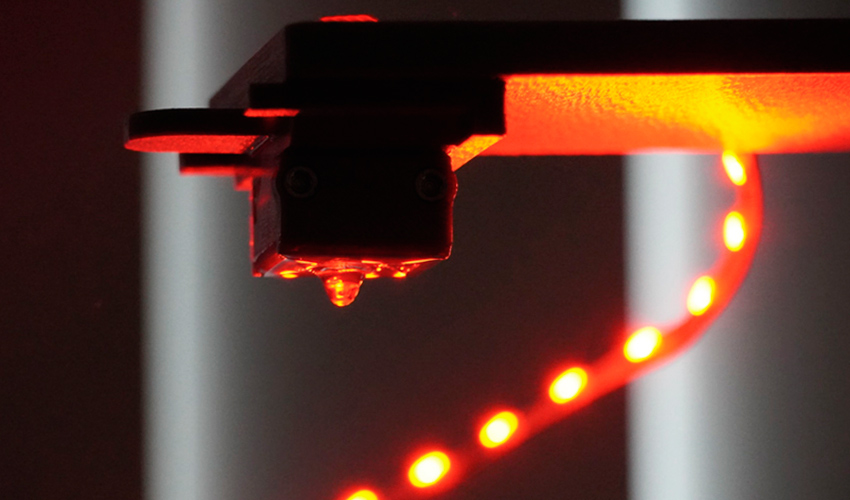

I am Vidmantas Sakalys, CEO of Vital3D Technologies. With a background in computer engineering, I have more than 20 years of practical experience in managing different information technology businesses. Later, fate decided to give me the opportunity to learn regarding the laser microfabrication industry and now I have been working with innovations in photonics for more than 10 years. Lasers are very good for 3D printing models that require very high precision. Therefore, knowledge regarding laser-based manufacturing led me to the field of 3D bioprinting.

Vidmantas Sakalys, CEO of Vital3D.

3DN: What is Vital3D? How did the idea to create the company come regarding?

Vital3D is a pioneering biotechnology company based in Lithuania, dedicated to innovating advanced solutions in medical research, drug discovery and regenerative medicine. Founded in 2021, Vital3D’s team of experts introduced innovative 3D bioprinting technology aimed at bridging the gap between organ supply and demand, specializing in 3D printing human organs, particularly the kidney. With a staff of 10, we have experts in lasers, biotechnology, software programming and mechanical engineering.

Having lost one of my mentors to urinary cancer, while working at a previous startup, I always wanted to create technology to help with these types of terminal illnesses. Together with a fellow laser scientist, we thought light might be a perfect tool for life sciences. Could we use it to print new human organs to deal with situations like the ones my mentor has had? Thus, at the end of 2021, the idea of a 3D bioprinter to print kidneys was born.

We are offering 3D printer Vital Light as a device for research institutions working in the field of life sciences. At the same time, we offer “printing as a service” for the creation of medical devices, tissues and organs. Our vision is to become a provider of 3D printing services for tissues and organs.

3DN: How does your 3D bioprinting technology work? What are its applications?

Vital3D’s bioprinting process is based on the use of laser light as a printing tool. Compared to the sprayed jet of molecules, this process uses a light source directed at the photosensitive bio-ink to harden the material under the “pressure” of light. The printed structure rises from the bioink pond. Imagine that you draw a picture with the pen, piece by piece coloring the entire picture. Now imagine that you have to paint the entire wall: with the pencil it will take forever. To paint faster we can use a wider brush to color larger areas. This is the essence of Vital3D’s dynamic light manipulation technology called FemtoBrush. The shape of the laser beam changes on the fly to represent the pencil, paintbrush, or even more sophisticated shapes like the ellipse.

Stent created using Vital3D technology.

By introducing this innovation in light-based bioprinting, we hope to address the challenge of vascularization in organ printing. The pen can be as small as 1 micron, to print the smallest vasculature, and switching to brush mode will help speed up the printing process hundreds of times, to allow printing of the entire kidney in 24 hours.

3DN: What are the main advantages of 3D printing? Are there limitations?

3D bioprinting of organs is a rapidly advancing field of medicine, but it has not yet reached the point where fully functional, transplantable human organs can be printed. Although there are reports of bioprinted tissues that have been successfully transplanted into animals, the leap to human transplantation is still in the future.

The complex biology of organ transplantation, the need for compatibility and long-term functionality are the challenges that researchers continue to work on. Vascularization (creation of blood vessels) of bioprinted tissues remains a major challenge. Without a functional vascular network, it is difficult to keep 3D printed organs alive and functional.

And what can we print in 3D now? Tissue and organ models, organoids (miniature), surgical models, custom and dental implants, prostheses, hearing aids, drug delivery devices, personalized surgical tools and, finally, patient-specific guides.

3DN: How do you see the future of 3D bioprinting in the medical field?

Although the long-term vision of printing any part of a human being is compelling, it is likely to be a gradual process that evolves over many years. Most researchers working in this field agree that between 15 and 20 years is a reasonable period for the first full-scale 3D bioprinted human organ to appear. As technology advances and understanding of biology deepens, a wider range of human body parts, from complex organs to intricate tissues, may be accessible for 3D printing and transplantation in the future. . I imagine that bioprinting will be able to extend the life of human beings, making the second part of our lives more pleasant.

Vital3D’s bioprinting system allows the creation of multiple models for personalized medicine.

3DN: Last words for readers?

The use of bioprinters in the medical field represents a promising and ethical change, not only in transplants, but also in disease research and drug development. Printing organoids or organ-on-chip models and tissues can create more human-like models (compared to current animal models) and would increase the precision and efficiency of the research process, ultimately leading to further advances in the field of medicine. Currently, the development of organ-on-chip models is experiencing exponential growth, suggesting a promising future for actively adapting this technology to research.

As technological innovations continue to improve the reproducibility, complexity, and scalability of organ-on-chip models, researchers will have an increasingly refined set of tools to understand human physiology and pathology. This progress can not only revolutionize our understanding of diseases at the cellular and molecular level, but also significantly reduce dependence on traditional methods of animal experimentation, ushering in a new era of more humane and effective approaches in biomedical sciences. You can find more information on the Vital3D website, here.

What do you think of the activity carried out by Vital3D? Leave your comments on our social networks: Facebook, Twitter y Youtube. Follow all the information regarding 3D printing in our weekly Newsletter.

*Credits for all photos: Vital3D

1709082995

#Vital3D #shapes #future #medicine #bioprinting #organs