A team of researchers recently announced that they have developed a new form of 3D printed heart valves. These parts are designed to give the patient’s own cells the opportunity to form new cells and grow with the rest of the body. This development should help reduce the complications associated with transplants. As you know, using the additive manufacturing in the medical sector has grown exponentially as it has allowed scientists and physicians to explore possibilities that were totally unimaginable just a few years ago. The project is still in the research and development phase but nevertheless represents a significant advance for the health sector.

The team includes Petra Mela, Professor of Medical Materials and Implants at the Technical University of Munich (TUM), and Professor Elena De-Juan Pardo from the University of Western Australia. Together, they worked on creating 3D-printed heart valves, which can be used as lifelong implants, due to their ability to form new tissue. Using additive manufacturing technologies, in combination with special, biodegradable materials, professionals have been able to create implants that replicate the unique complexities of a human organ.

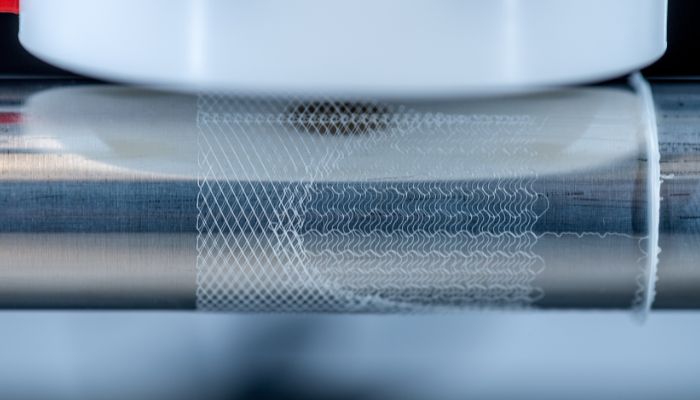

The 3D printed valves are very detailed (photo credits: Andreas Heddergott / TUM)

Although there are already other types of heart valve implants, their use always comes with different complications. Mechanical valves, for example, tend to form blood clots on metal surfaces, which can lead to serious complications. In addition, patients must take blood thinners for life and limit their physical activity. Another downside is that these valves cannot grow and eventually have to be replaced, as Petra Mela explains: “ Our goal is to design bio-inspired heart valves that promote the formation of new functional tissues in patients. Children would especially benefit from such a solution, as current heart valves do not grow with the patient and need to be replaced over the years in multiple surgeries. Our heart valves, on the other hand, mimic the complexity of natural heart valves and are designed to allow the patient’s cells to seep into the scaffold. »

The use of special technology for 3D printed heart valves

To be able to mimic the fine biological structures of the human organ, the researchers turned to a completely new technology of fabrication additive, called “melt electrowriting”. It is essentially an extrusion process in which a polymer is heated, melted and expelled from a printhead as a liquid jet. However, the particularity of this process lies in the use of a high voltage electric field, which is applied to the jet and makes the resulting fiber as thin as five to fifty micrometers, which allows the machine to print extremely detailed manner and produce highly accurate models. To ensure the best material is used for the implant, the team chose to use medical grade polycaprolactone (PCL), which is cell compatible and biodegradable.

Petra Mela, professor of medical materials and implants at the Technical University of Munich

As stated earlier, the long-term goal is to create implants for children that can stay inside the body and grow with the patient. The hope is that over time the cells settle into the micro pore spaces, which are smaller than the pores in the PCL structure. Although there is still a long way to go, the team is convinced that this is a great improvement for people with heart valve disease and will soon move into animal testing. To learn more regarding the project, click ICI.

What do you think of these 3D printed valves? Share your opinion in the comments of the article. Find all our videos on our channel YouTube or follow us on Facebook or Twitter !

*Cover photo credits: Andreas Heddergott / TUM