Lhe many export successes of the Rafale in 2021 will continue in 2022. At the start of the year, contracts were signed with the United Arab Emirates for 80 F4 standard aircraft, the largest contract ever signed by the aircraft manufacturer. tricolor. New buyer, Indonesia – eighth customer and seventh for export – wants 42 Rafale. In 2021, the three aeronautical companies of Team Rafale, the aircraft manufacturer Dassault Aviation, the engine manufacturer Safran and the equipment manufacturer Thales, placed an order for 49 new Rafale (Egypt 30 + 1, France 12, Greece 6) and 12 from occasion (Greece) taken on the park of the French air force. 31e Rafale for Egypt comes from a budget tail left by the first order of 2011. This is the official explanation. Unless it is the replacement of a device lost in training. The order book as of December 31, 2021 now includes 86 new Rafale (46 Export, 40 France), while Croatia has requested 6 used aircraft, ex-tricolors. Among the prospects are Serbia and Iraq (payable in oil!). Currently being negotiated, two contracts with India relate to 114 planes for the air force and 57 for the navy embarked on aircraft carriers.

READ ALSONew Rafale for Egypt: a success and questions

Too expensive

“The Rafale is too expensive” (around 100 million euros), it was said before this reversal occurred ten years ago with a first export order from Egypt. “It’s not that expensive, given what it can do,” says Éric Trappier, CEO of Dassault Aviation. The same aircraft can, sometimes during the same mission, provide airspace security, reconnaissance, attack on the ground or at sea, etc. Other competing offers require several specialized devices, which is much more expensive and cumbersome to deploy.

In terms of jobs, the whole of aeronautical France is watered by Rafale contracts which concern 400 companies in large areas such as Bordeaux, Toulouse and the Paris region, but also unexpected regions such as the Alpine valleys where flight orders and specialized parts close to watchmaking. Let’s not forget that on this strategic aircraft, everything must be made in France, so as not to risk being deprived of spare parts during a conflict. “The production of the Rafale at a rate of one, at the rate of one per month or eleven per year, mobilizes 7,000 jobs throughout the Rafale system with Dassault, Safran and Thales, not including development”, indicates Dassault Aviation. And we plan to go to rate 3! This rise in power is a topical and worrying subject in the supply chain. These mistreated by the Covid must reconstitute their teams to hold production. “And a screw of 5 late can block the chain outlet of an aircraft”, warns Éric Trappier.

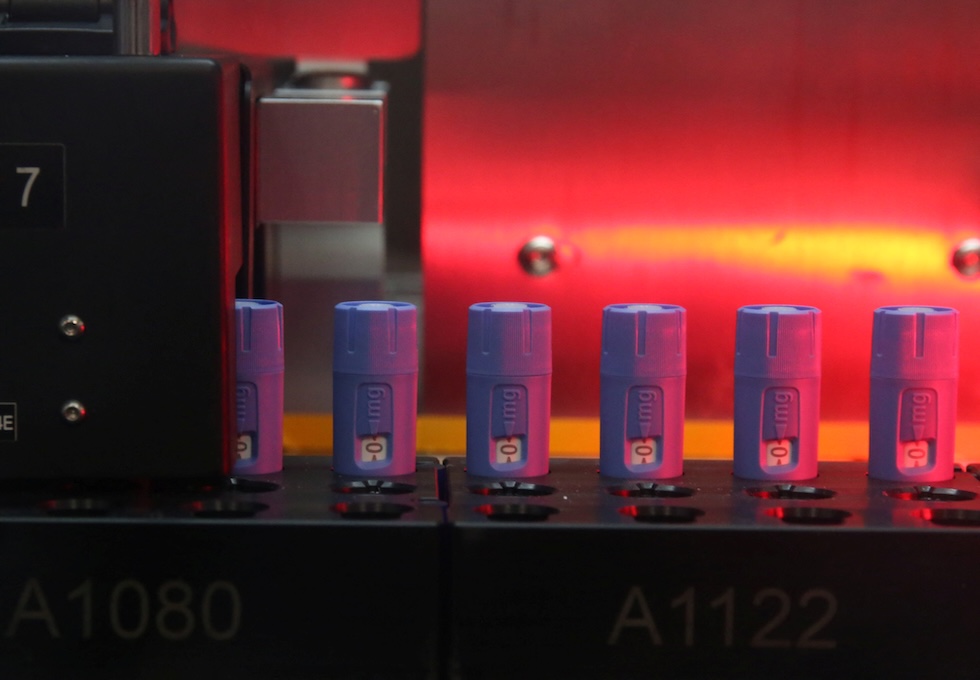

Another figure often quoted, a Rafale ordered in addition represents one hundred additional jobs. The share of the cake can vary according to the options chosen by the customer and 18% is generally attributed to Thales (radar, optronics, protection and telecommunications systems), 25% to Safran (M88 engines, landing gear, brakes, seat ejector) and the rest to Dassault Aviation. Thales, controlled by Dassault Aviation, which recruited 6,000 to 7,000 employees year following year, is looking for 11,000 this year, including 3,500 in France. Comparable figures are announced by Safran. Partly also to respond to the success of the Rafale.