Europe Needs Cluster Munitions: Strategic Necessity?

Europe’s Defense Dilemma: Reconsidering Cluster Munitions Amidst Rising russian threat WASHINGTON — As tensions escalate between NATO and Russia, a provocative question is emerging in

Europe’s Defense Dilemma: Reconsidering Cluster Munitions Amidst Rising russian threat WASHINGTON — As tensions escalate between NATO and Russia, a provocative question is emerging in

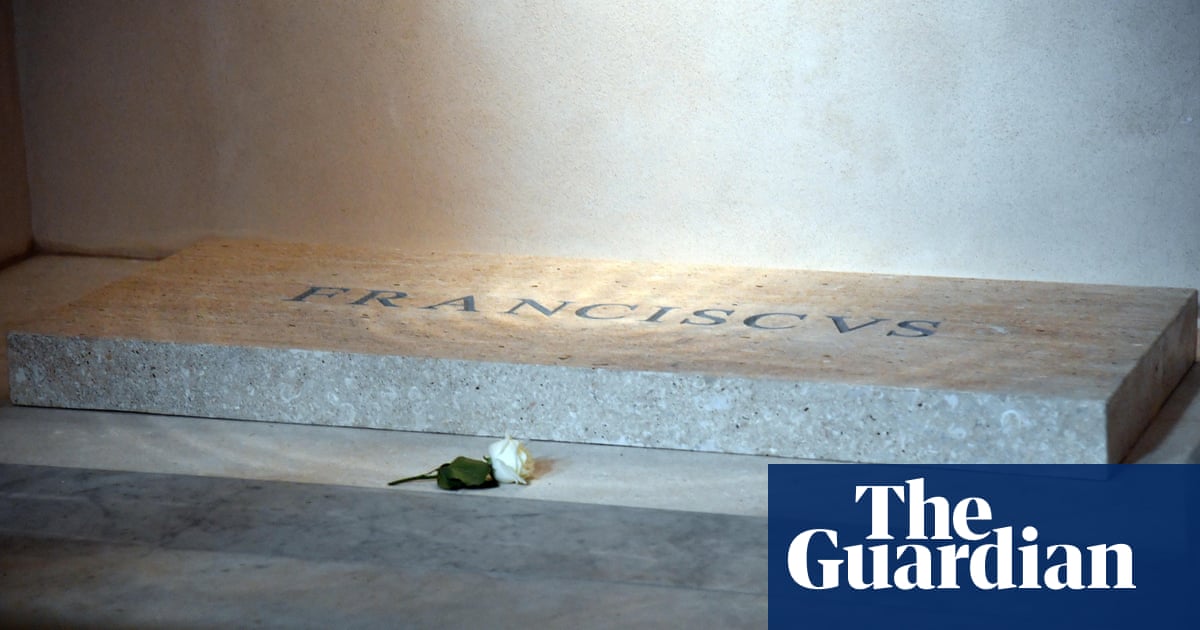

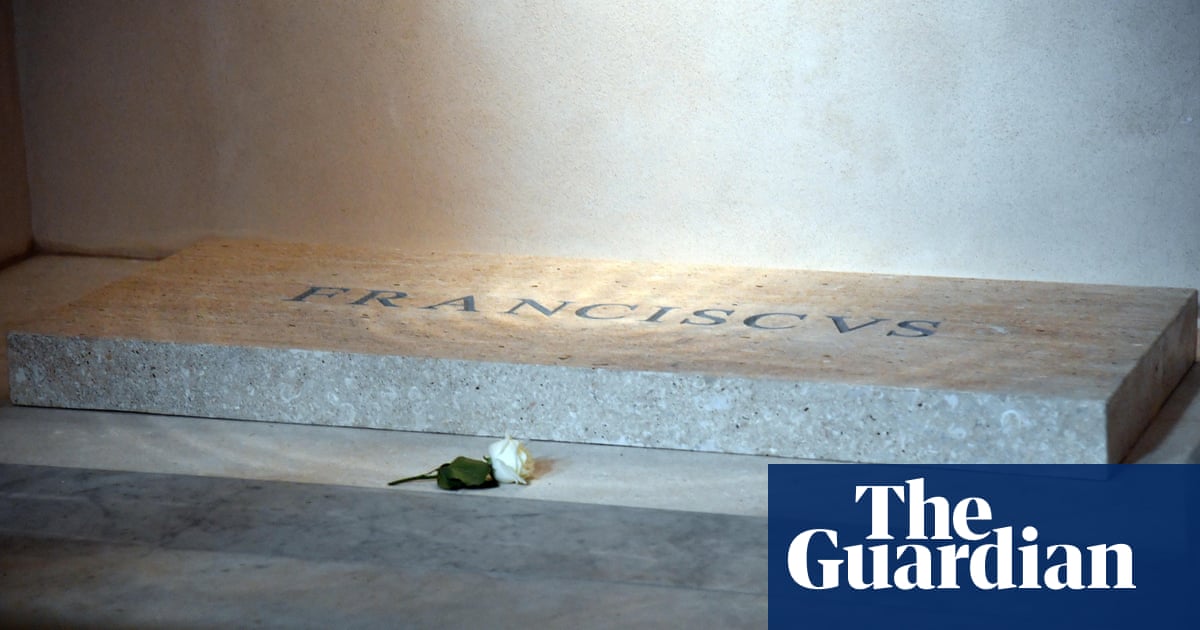

pilgrims Pay Respects at Pope Francis‘s Tomb as Conclave Looms Table of Contents 1. pilgrims Pay Respects at Pope Francis’s Tomb as Conclave Looms 2.

Shedeur Sanders Embraces Browns Challenge, Aims to Prove Himself After Draft Slide By Archyde News Service May 2, 2025 Cleveland, OH—Shedeur Sanders, the highly touted

Here’s a rewritten and expanded news feature based on the provided source, adhering to your specifications: Google Pixel 9a: Unlock It’s True Potential With These

Europe’s Defense Dilemma: Reconsidering Cluster Munitions Amidst Rising russian threat WASHINGTON — As tensions escalate between NATO and Russia, a provocative question is emerging in

pilgrims Pay Respects at Pope Francis‘s Tomb as Conclave Looms Table of Contents 1. pilgrims Pay Respects at Pope Francis’s Tomb as Conclave Looms 2.

Shedeur Sanders Embraces Browns Challenge, Aims to Prove Himself After Draft Slide By Archyde News Service May 2, 2025 Cleveland, OH—Shedeur Sanders, the highly touted

Here’s a rewritten and expanded news feature based on the provided source, adhering to your specifications: Google Pixel 9a: Unlock It’s True Potential With These

© 2025 All rights reserved