In the current context of rising demand for renewable energy, the recycling and recovery of materials from clean technologies, such as solar panels, have become crucial issues. Solar panels contain valuable metals like aluminum, steel, copper, zinc, and silver and have a lifespan of approximately thirty years. When they reach the end of their life cycle, recovering these metals is essential not only to reduce environmental impact but also to decrease reliance on mining extraction.

Efficient Recovery of Silver and Other Metals in Solar Panels

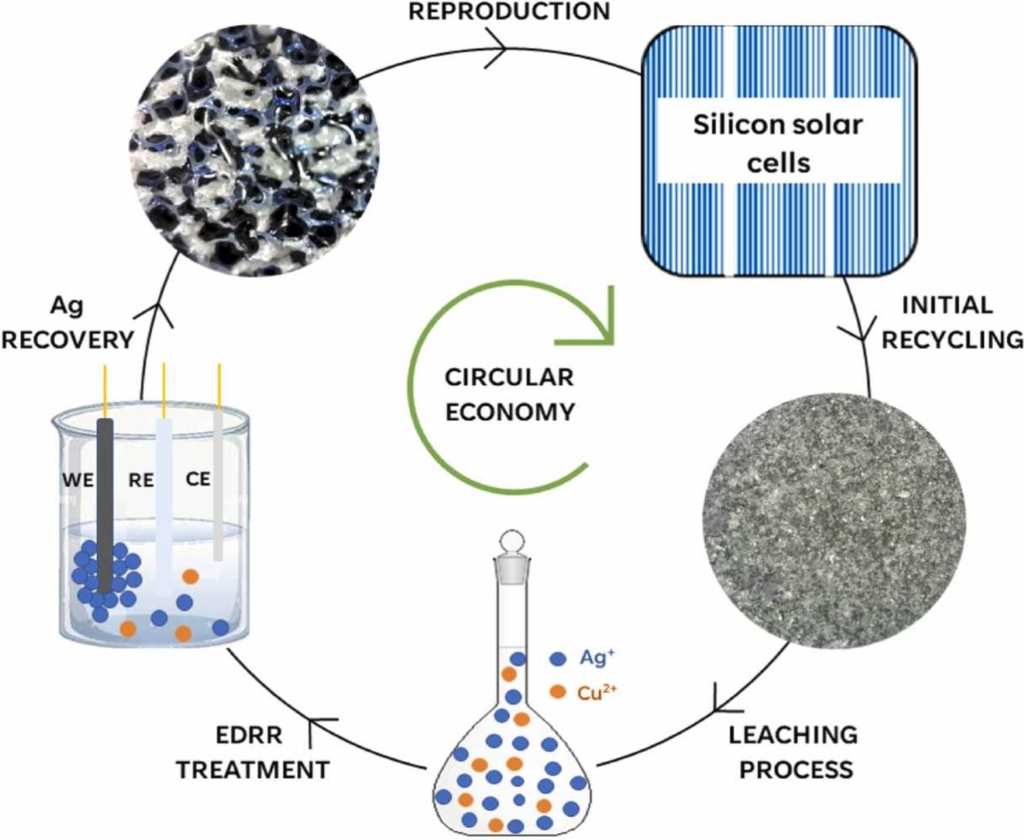

Scientists at the University of Camerino in Italy have developed an innovative method that combines hydrometallurgy and electrochemical deposition, achieving up to 98.7% recovery of the silver found in discarded solar cells. This technique is not only more efficient than traditional methods but is also more environmentally friendly, as it decreases energy consumption and the need for additional chemicals.

Importance of Metal Recovery

The increase in the installation of large-scale solar plants is driving a growing demand for metals such as silver and copper, which are critical for the functionality of solar panels. Given that these metals are limited in the earth’s crust, their recovery becomes vital for ensuring the sustainability of the renewable energy supply chain. Additionally, recovering metals from discarded products is significantly less energy-intensive than conventional mining, representing a greener and more cost-effective alternative.

Challenges in the Separation of Copper and Silver

One of the major challenges in recovering metals from solar panels is separating copper and silver due to their closely related reduction potential values, complicating the leaching process. To tackle this issue, the researchers utilized persulfate activated with a base and ammonia, where persulfate serves as an oxidizing agent. This approach generates copper oxide, which forms a protective layer hindering its leaching, thereby facilitating efficient separation of silver.

In laboratory tests, it was found that a concentration of 0.5 M ammonia and 0.2 mol per liter of persulfate, with a reaction time of 60 minutes, achieved an 85% efficiency in silver separation. Nonetheless, to enhance efficiency further, the team implemented an advanced electrochemical process.

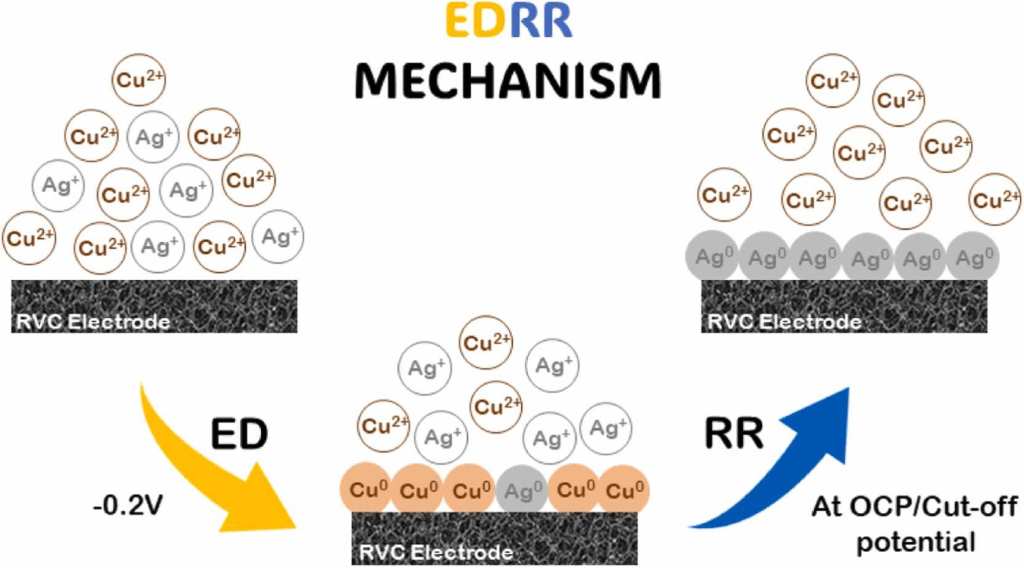

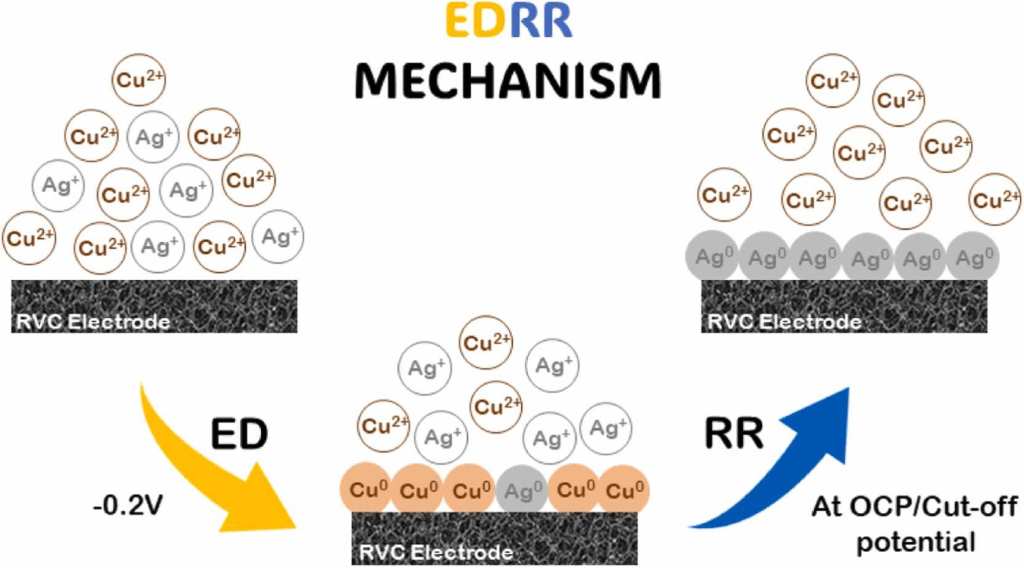

Advanced Electrodeposition-Redox (EDRR) Technique

The electrowinning redox replacement (EDRR) technique was chosen for its capability to directly separate high-purity silver from a leachate containing copper ions, eliminating the need for additional chemicals. This method is highly selective for silver and allows for precious metals to be recovered with an efficiency of up to 98.7%, making it a superior choice compared to traditional processes.

Environmental Impact and Economic Benefits

Implementing techniques such as those developed by the University of Camerino not only enhances the efficiency of recovering valuable metals but also reduces the environmental impact associated with disposing of used solar panels. By minimizing the need for new mining activities, these techniques support the preservation of ecosystems and the reduction of carbon emissions, aligning with global sustainability and environmental protection objectives.

More information: www.sciencedirect.com

If you liked this article, please share it with your friends on social media. Thank you!

In the current context of increasing demand for renewable energy, recycling and recovery of materials from clean technologies such as solar panels have become crucial issues. Solar panels, composed of valuable metals such as aluminum, steel, copper, zinc, and silver, have a useful life of approximately three decades. When they reach the end of their life cycle, the recovery of these metals is not only vital to mitigate the environmental impact but also to reduce dependence on mining extraction.

Efficient Recovery of Silver and Other Metals in Solar Panels

Scientists at the University of Camerino in Italy have developed an innovative technique that combines hydrometallurgy and electrochemical deposition, managing to recover up to 98.7% of the silver contained in disused solar cells. This method, compared to conventional techniques, is not only more efficient but also more environmentally friendly, as it reduces energy consumption and the need for additional chemicals.

Importance of Metal Recovery

The rise in the installation of large-scale solar plants is creating a growing demand for metals such as silver and copper, which are essential for the operation of solar panels. Since these metals have limited availability in the earth’s crust, their recovery becomes critical to ensure the sustainability of the renewable energy supply chain. In addition, the recovery of metals from discarded products is significantly less energy-intensive than traditional mining, representing a greener and more economical alternative.

Challenges in the Separation of Copper and Silver

One of the main challenges in recovering metals from solar panels is the separation of copper and silver, because their reduction potential values are very close, complicating the leaching process. To overcome this difficulty, the researchers used persulfate activated with a base and ammonia, where persulfate acts as an oxidizing agent. This process produces copper oxide, which forms a protective layer that prevents its own leaching, allowing the effective separation of silver.

In laboratory tests, it was determined that a concentration of 0.5 M ammonia and 0.2 mol per liter of persulfate, with a reaction time of 60 minutes, resulted in an efficiency of 85% in the separation of silver. However, to improve efficiency even further, the team turned to the use of an advanced electrochemical process.

Advanced Electrodeposition-Redox (EDRR) Technique

The electrowinning redox replacement (EDRR) technique was selected due to its ability to separate high purity silver directly from a leachate containing copper ions, without the need to add additional chemicals. This method is highly selective for silver and allows precious metals to be recovered with an efficiency of up to 98.7%, making it a superior option to conventional processes.

Environmental Impact and Economic Benefits

The implementation of techniques such as those developed by the University of Camerino not only improves the efficiency of recovering valuable metals but also minimizes the environmental impact associated with the disposal of disused solar panels. By reducing the need for new mining operations, these techniques contribute to the preservation of ecosystems and the reduction of carbon emissions, aligning with global sustainability and environmental protection goals.

Benefits and Efficient Practices for Metal Recovery

- Reduced Environmental Impact: Using recovery methods minimizes landfill waste and avoids the ecological damage associated with traditional mining.

- Resource Efficiency: Reusing metals like silver and copper decreases the reliance on newly mined materials and lowers production costs.

- Innovation in Recycling Technologies: Continuous advancements in recovery techniques can enhance the efficiency and yield from obsolete solar technologies.

Case Studies and Practical Experiences

Several companies have begun to adopt advanced recovery techniques to optimize their solar panel disposal processes. For instance, firms focusing on sustainability often report substantial financial savings and improved public perception by adopting eco-friendly recycling practices.

| Company | Technique Used | Recovery Efficiency | Environmental Impact Reduction |

|---|---|---|---|

| GreenTech Solar | Hydrometallurgy & EDRR | 90% | 80% Reduction in Carbon Footprint |

| EcoPanel Recycling | Advanced Electrochemical Techniques | 95% | 50% Less Landfill Waste |

| Solar Reclaim | Innovative Leaching Processes | 85% | Reduction in Ecosystem Disturbance |

More information: www.sciencedirect.com

If you liked this article, please share it with your friends on social media. Thank you!