Gain in volume and weight, resistance to high temperatures, high voltages and radiation, quantum applications…, synthetic diamond is an advanced material, which has exceptional properties and offers a wide range of applications. Expert in this field, the French start-up DIAMFAB continues its development.

We interviewed Gauthier Chicot, president of DIAMFAB, who had already presented the young company to us in early 2022.

According to him, 2023 will be a pivotal year for this Deeptech start-up which wishes to accelerate its development, launch fundraising and start collaborations with industrial players.

DIAMFAB is a start-up founded in March 2019.

This CNRS spin-off offers the semiconductor industry its unique know-how resulting from 30 years of R&D in diamond technology.

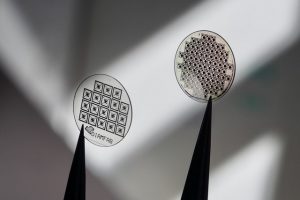

The electronic quality diamond technology offered by DIAMFAB already makes it possible to manufacture diamond wafers with perfectly controlled electronic properties.

The development of converters 80% more compact and efficient than those designed with silicon components is one of the many potential applications.

Engineering Techniques: Last year, you mentioned the arrival of employees for 2022. Have you recruited new profiles to accelerate your development?

Gauthier CHICOT: In fact, in 2022, our team was considerably strengthened, with the reception of two doctoral students as part of CIFRE theses and the recruitment of an R&D engineer and two engineers on work-study programs on R&D projects.

We also welcomed Ivan Llaurado, a very experienced collaborator from the world of industry, whose role within DIAMFAB is to create new industrial partnerships.

Can you say more regarding these projects on which DIAMFAB is involved?

In 2022, DIAMFAB started two major R&D projects.

The first is called LSD-MOSFET and consists of obtaining transistors on large diamond wafers. It is a project in partnership with the Néel Institute and the LAboratoire PLAsma et Conversion d’Energie (LAPLACE) which is supported by the ANR[1].

At present, we have mastered the fabrication of MOSFETs on small-sized substrates. To interest manufacturers, we must now successfully produce larger wafers, which is also part of our roadmap.

The other project (Tbatt-Diamond) is quite different, as it concerns the production of beta voltaic batteries. The goal is to develop batteries with a lifespan of 20 years by incorporating tritium from nuclear waste into an elementary diamond cell.

The principle of the beta voltaic battery is nevertheless not new, since it is a technology already used in space. The major difference is that instead of using more conventional semiconductors (Si, SiC), we are working on the use of diamond, because there are several advantages.

On the one hand, as diamond is a so-called “large gap” material, it has the ability to convert radioactive energy into electricity more efficiently. On the other hand, once the tritium atoms have been “infused” into the diamond, their desorption is blocked at the temperatures of use ensuring sealing under normal conditions.

On this project, supported by France 2030, DIAMFAB is working in partnership with the CEA and STMicroelectronics, which is in charge of all the Energy Harvesting part.

Finally, DIAMFAB is also involved in two theses and also participates in the H2020 CleanSky II project.

DIAMFAB develops solutions for the energy transition. Are you also looking to improve your carbon footprint?

Energy conversion (and therefore power electronics) is at the heart of the energy transition. Nevertheless, we want to go further on these issues and we are implementing actions to quantify and improve our carbon footprint.

For example, we are thinking regarding replacing the gases used in our process (methane and hydrogen) with biosourced or sustainable alternatives. We also try to quantify the carbon footprint of our process, taking into account the energy consumed by the machines and we make sure to control CO emissions.2 related to our travels.

Has the fundraising planned for 2022 taken place?

There has been a change on this side, because we have decided to postpone the fundraising initially planned for 2022, in particular to refine our strategy and our needs.

This year, we have just launched a fundraiser of up to €3 million. We are therefore looking for financial partners, but not only. DIAMFAB also needs industrial partners interested in the co-development of new products. For us, this is a pivotal year, so we are open to proposals for collaboration.

[1] Project ANR-21-CE50-0036, lasting 48 months, supported by the ANR to the tune of €584,079