Rewrite the provided article:

Before the rise of pears and apples, the Alto Valley was land dedicated to growing grapevines.In the early 20th century, breweries proliferated in every town. Coopermaking was a necessary occupation at the time, but The evolution of the industry makes it disappear.

“Until the 1960s, the most common continental What is used to transport wine? This is called “Poldelez” (commonly known as “bordalesa”) has about 180 or 200 liters. With the movement of loading and unloading, in addition to the transfer of trucks or train cars, The stick is loose [maderas] This causes it to start leaking Therefore, the cooper’s main job is to dismantle the Bordeaux and restore its use by inserting reed leaves between the staves. that job This is called “caulking”.

“All wineries, depending on the amount of wine they produce, have one, two, three or more coopers,” he said. Engineer and teacher Federico WitkowskiDedicated to restoring the history of dozens of wineries, on its Facebook page “Poster for Bordeaux wines from northern Patagonia.”

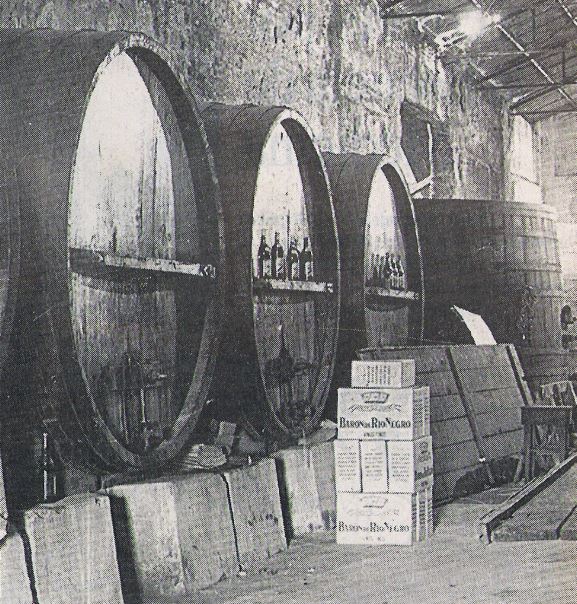

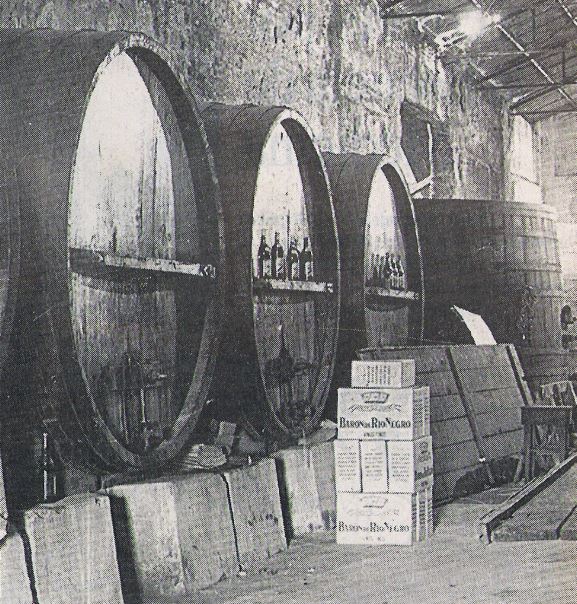

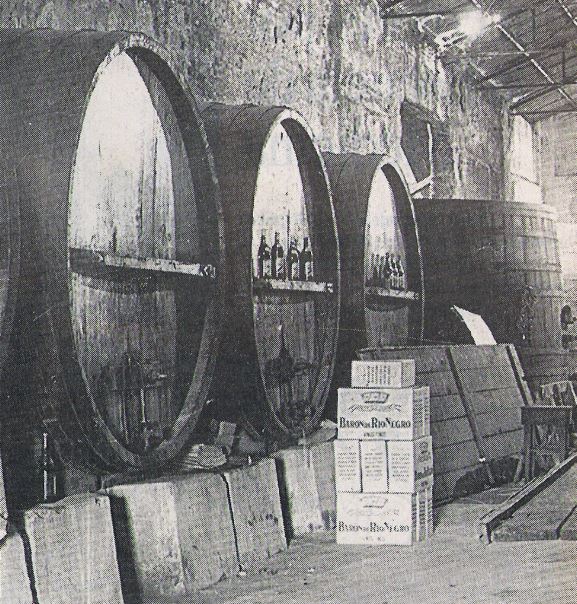

Part of the Bodega Canale Archives – Photo: Juan Thomes.

Part of the Bodega Canale Archives – Photo: Juan Thomes.

***

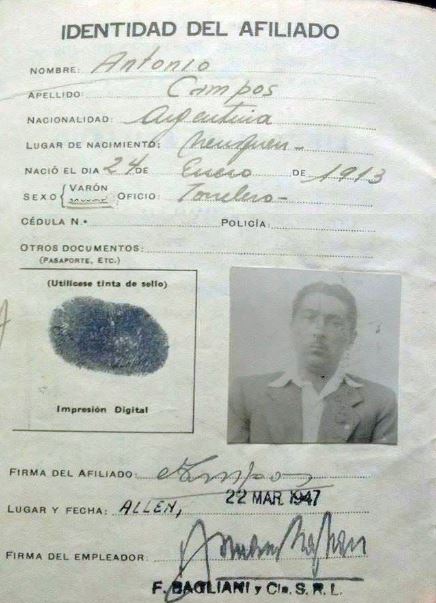

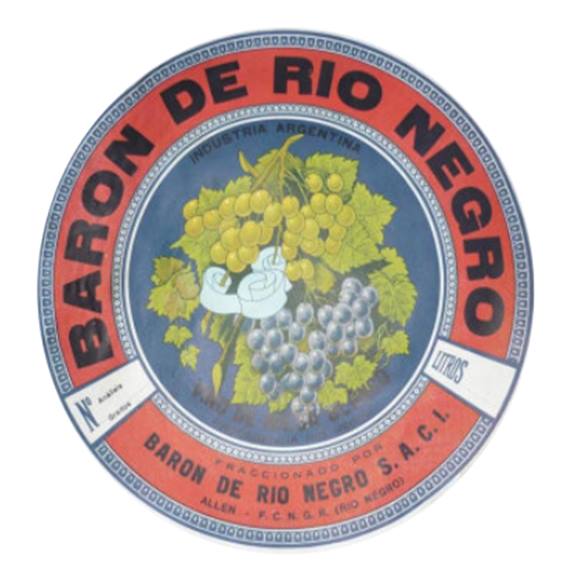

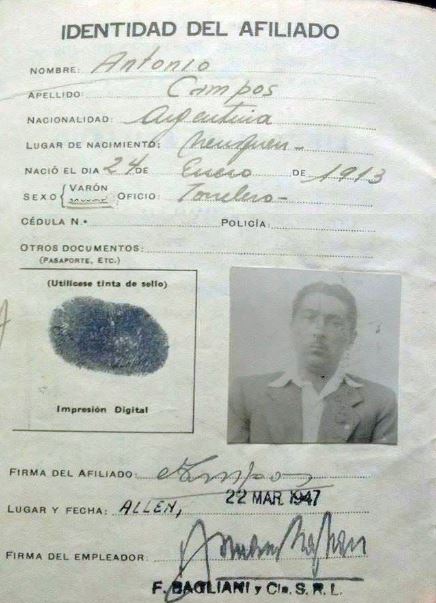

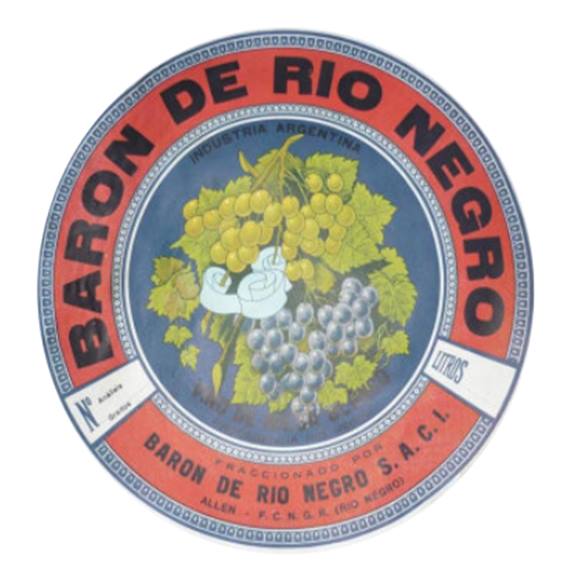

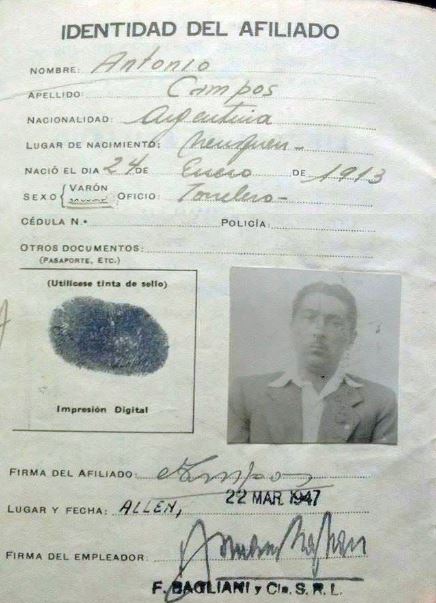

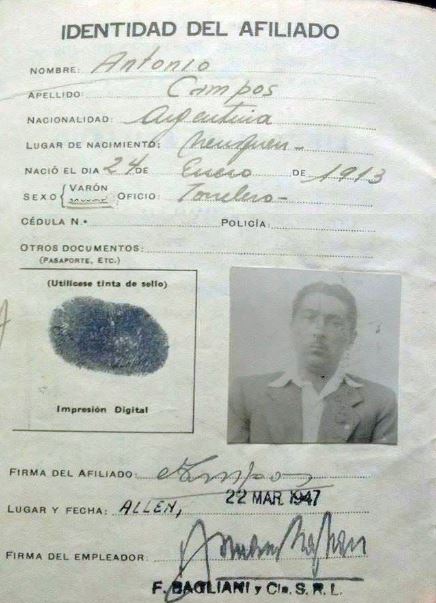

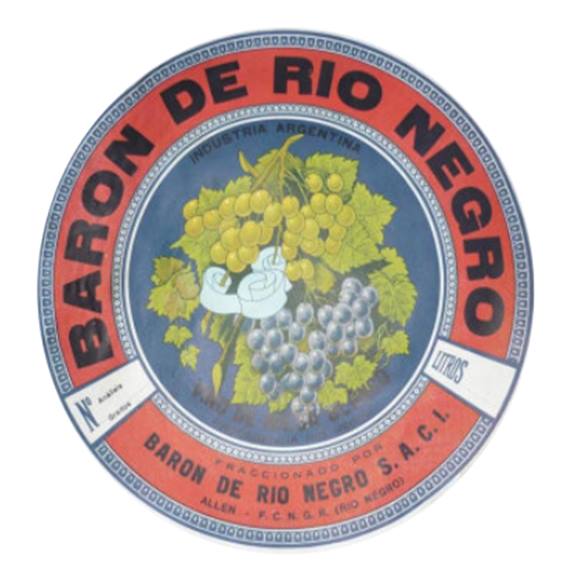

Antonio Campos is one of the Coopers, “Campito” His neighbors called him this. There aren’t many of these craftsmen, so they become experts in their fields and are therefore in high demand.. The iconic “Baron Rio Negro”, The second phase of the groundbreaking “Los Viñedos” existed before Allen founded it, and he was one of the company’s employees. Every morning, his children would set off on his red bicycle Complete a shift at a property currently operating in a local industrial parkLocated next to Cunmalleu Ceramics in Biló Access.

Neuquino de la Confluencia, born 1913returning each afternoon to continue processing some specific requests, in this case with homemade winehe solved the problem in a studio he set up in his home. “They have never Allen, Fernández Oro and Guerrico’s farmswith big trucks and vans,” recalled his daughter Lydia. Antonio’s first experience working in a production area was on the land owned by the family of Manuel Mir, also in Allen, who also ran a winery there.

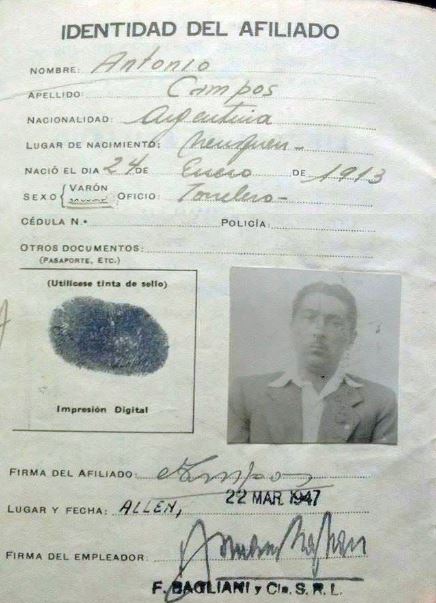

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.***

Photo: Facebook “Boldelei Poster…”

Photo: Facebook “Boldelei Poster…”***

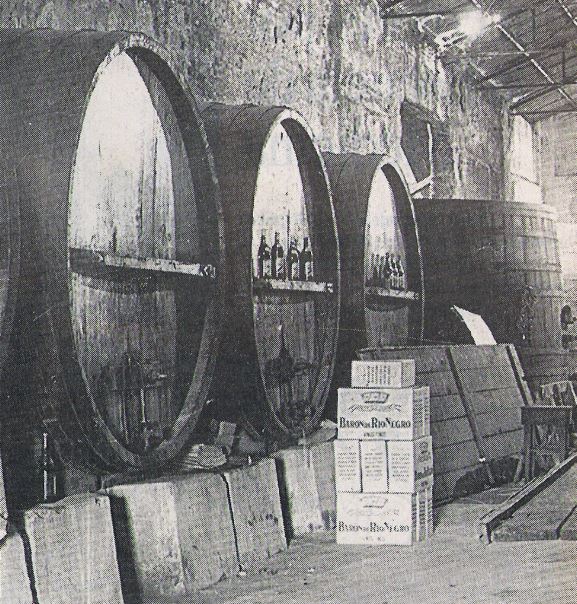

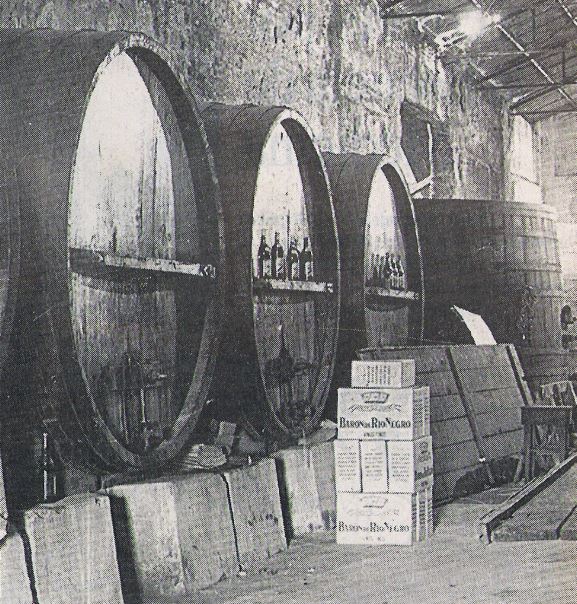

In Roca, coopers had a similar experience; They worked on the centenary production of Humberto Canale, As its brand says, it’s been in effect since 1909. Very similar to the scene seen in “Campito” Every day: huge barrels with a capacity of over 27,000 liters, made of high-quality wood Oak from the Nancy region of Francethose things that shelter the expected grape fruit.

Today’s natural containers, They have not been used in at least 15 years., But it still needs to be kept moistso they don’t dry out and ruin the perfect fit that’s kept them assembled for nearly a century. “They are only cleaned with pressurized water, without any cleaning products,” he stressed. Horacio Bibiloni, corporate winemakertalk to RÍO Negro.

Photo: Juan Tomes.

Photo: Juan Tomes. ***

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In front of those huge wooden barrels, Accessories such as curtains are displayed on the walls.a French term referring to the “valve” used to empty the contents after the aging process. The seal on the cover faces people who stop to admire it. It still displays its French origins as a brand as a guarantee of quality.

Although the coopers require manual, patient, and precise work, it is important to note that none of these barrels are made or shaped in Argentina, but rather shipped from Europe and then assembled at their final destination. This kind of logistics leads to Maintain a service life of at least several decadesas far as Canale is concerned, continuity is through Two workers, working together to maintain 100 of these giants. At the same time, Bordeaux wine barrels, also known today as “casks”, appeared, which were of smaller capacity and were used for transportation and sales.

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In this case, Witkovsky raised this question: why they disappeared Mr. and Mrs. Cooper when? “Beginning in the late 1960s and early 1970s, the National Institute of Viticulture (INV) issued a resolution Distribution of famous “loose wine” banned in Bordeaux” said the expert. “The operation of these vessels consisted of placing them horizontally, inserting a wooden spigot called a spigot, and punching a hole in the top slat so that air could enter and the wine could drain out easily. The vent is then covered with a dowel, also made of wood, called an “espiche”,” he added.

Health measures mandate use of glass for half johns and bottles, forcing winemakers to make changes Integrated washing machinery The quantity of these containers exceeds economic possibilities, especially for the smallest producers. “this produce closure Many institutions because they cannot afford these costs,” the engineer added.

Photo: The Allen Project.

Photo: The Allen Project.***

Therefore, Antonio’s profession is losing demand which forces him to retire while In addition to the “garzador”, there are also tools such as the “garlopa” (planer), hammer and “chazo” for lowering the hoop (metal ring). Today, work similar to what he did is carried out in Canale, for example, by two trained operators, since this is mass production, but they are not classified as coopers. “Currently, there is a trend towards using oak containers again, with larger capacities, we are talking about 6800 liters, and the life of these oak barrels will be longer, so maybe after a while we will have to restore this digital cooper ,” Bibiloni admitted.

Meanwhile, Allen launched an initiative Seeking limited work, betting on the organic and artisanal, makes Daniel González and his team “Juan de Ferena” will be trained in knowledge that seems dormant.. As owners of the González Acuña family winery, they are responsible for restoring Second-use barrels, brought into the country Importers in Mendoza and Buenos Aires have been aging their products for four years, but have only registered the trademark for one.

Photo: Instagram.

Photo: Instagram.***

In this context It’s hard to get the same tools as last yearDaniel and his people managed to find alternatives among the current options and achieve the same results. Do not leave residue on the wood, do not use glue and disinfect These are the prerequisites to avoid contaminating the wine, so the rest comes down to perseverance and curiosity.

As if time has never passed, Reed rods continue to be an ally in ensuring airtightness Between the “staff”, through Steam, ozone gas and sulfuranother original resource that has received a lot of attention. “We do all the work by hand and after the fermentation tanks are produced Once in barrel, it can be stored for 12 months, 18 months and up to 24 months. Our annual production is about 3,000 bottles, but we expect that to double next year,” Daniel predicts. Temperature-controlled production rooms with increasing technical details are in operation A few blocks from downtown Allen and the exit to Fernández Oro, corner of Mariani and Alte streets. brown.

Photo: Instagram.

Photo: Instagram.

into a high-quality, completely original piece for my website.

The rewritten article must:

Be entirely reimagined and rewritten, with no sentences or phrasing resembling

Before the rise of pears and apples, the Alto Valley was land dedicated to growing grapevines.In the early 20th century, breweries proliferated in every town. Coopermaking was a necessary occupation at the time, but The evolution of the industry makes it disappear.

“Until the 1960s, the most common continental What is used to transport wine? This is called “Poldelez” (commonly known as “bordalesa”) has about 180 or 200 liters. With the movement of loading and unloading, in addition to the transfer of trucks or train cars, The stick is loose [maderas] This causes it to start leaking Therefore, the cooper’s main job is to dismantle the Bordeaux and restore its use by inserting reed leaves between the staves. that job This is called “caulking”.

“All wineries, depending on the amount of wine they produce, have one, two, three or more coopers,” he said. Engineer and teacher Federico WitkowskiDedicated to restoring the history of dozens of wineries, on its Facebook page “Poster for Bordeaux wines from northern Patagonia.”

Part of the Bodega Canale Archives – Photo: Juan Thomes.

Part of the Bodega Canale Archives – Photo: Juan Thomes.

***

Antonio Campos is one of the Coopers, “Campito” His neighbors called him this. There aren’t many of these craftsmen, so they become experts in their fields and are therefore in high demand.. The iconic “Baron Rio Negro”, The second phase of the groundbreaking “Los Viñedos” existed before Allen founded it, and he was one of the company’s employees. Every morning, his children would set off on his red bicycle Complete a shift at a property currently operating in a local industrial parkLocated next to Cunmalleu Ceramics in Biló Access.

Neuquino de la Confluencia, born 1913returning each afternoon to continue processing some specific requests, in this case with homemade winehe solved the problem in a studio he set up in his home. “They have never Allen, Fernández Oro and Guerrico’s farmswith big trucks and vans,” recalled his daughter Lydia. Antonio’s first experience working in a production area was on the land owned by the family of Manuel Mir, also in Allen, who also ran a winery there.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.***

Photo: Facebook “Boldelei Poster…”

Photo: Facebook “Boldelei Poster…”***

In Roca, coopers had a similar experience; They worked on the centenary production of Humberto Canale, As its brand says, it’s been in effect since 1909. Very similar to the scene seen in “Campito” Every day: huge barrels with a capacity of over 27,000 liters, made of high-quality wood Oak from the Nancy region of Francethose things that shelter the expected grape fruit.

Today’s natural containers, They have not been used in at least 15 years., But it still needs to be kept moistso they don’t dry out and ruin the perfect fit that’s kept them assembled for nearly a century. “They are only cleaned with pressurized water, without any cleaning products,” he stressed. Horacio Bibiloni, corporate winemakertalk to RÍO Negro.

Photo: Juan Tomes.

Photo: Juan Tomes. ***

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In front of those huge wooden barrels, Accessories such as curtains are displayed on the walls.a French term referring to the “valve” used to empty the contents after the aging process. The seal on the cover faces people who stop to admire it. It still displays its French origins as a brand as a guarantee of quality.

Although the coopers require manual, patient, and precise work, it is important to note that none of these barrels are made or shaped in Argentina, but rather shipped from Europe and then assembled at their final destination. This kind of logistics leads to Maintain a service life of at least several decadesas far as Canale is concerned, continuity is through Two workers, working together to maintain 100 of these giants. At the same time, Bordeaux wine barrels, also known today as “casks”, appeared, which were of smaller capacity and were used for transportation and sales.

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In this case, Witkovsky raised this question: why they disappeared Mr. and Mrs. Cooper when? “Beginning in the late 1960s and early 1970s, the National Institute of Viticulture (INV) issued a resolution Distribution of famous “loose wine” banned in Bordeaux” said the expert. “The operation of these vessels consisted of placing them horizontally, inserting a wooden spigot called a spigot, and punching a hole in the top slat so that air could enter and the wine could drain out easily. The vent is then covered with a dowel, also made of wood, called an “espiche”,” he added.

Health measures mandate use of glass for half johns and bottles, forcing winemakers to make changes Integrated washing machinery The quantity of these containers exceeds economic possibilities, especially for the smallest producers. “this produce closure Many institutions because they cannot afford these costs,” the engineer added.

Photo: The Allen Project.

Photo: The Allen Project.***

Therefore, Antonio’s profession is losing demand which forces him to retire while In addition to the “garzador”, there are also tools such as the “garlopa” (planer), hammer and “chazo” for lowering the hoop (metal ring). Today, work similar to what he did is carried out in Canale, for example, by two trained operators, since this is mass production, but they are not classified as coopers. “Currently, there is a trend towards using oak containers again, with larger capacities, we are talking about 6800 liters, and the life of these oak barrels will be longer, so maybe after a while we will have to restore this digital cooper ,” Bibiloni admitted.

Meanwhile, Allen launched an initiative Seeking limited work, betting on the organic and artisanal, makes Daniel González and his team “Juan de Ferena” will be trained in knowledge that seems dormant.. As owners of the González Acuña family winery, they are responsible for restoring Second-use barrels, brought into the country Importers in Mendoza and Buenos Aires have been aging their products for four years, but have only registered the trademark for one.

Photo: Instagram.

Photo: Instagram.***

In this context It’s hard to get the same tools as last yearDaniel and his people managed to find alternatives among the current options and achieve the same results. Do not leave residue on the wood, do not use glue and disinfect These are the prerequisites to avoid contaminating the wine, so the rest comes down to perseverance and curiosity.

As if time has never passed, Reed rods continue to be an ally in ensuring airtightness Between the “staff”, through Steam, ozone gas and sulfuranother original resource that has received a lot of attention. “We do all the work by hand and after the fermentation tanks are produced Once in barrel, it can be stored for 12 months, 18 months and up to 24 months. Our annual production is about 3,000 bottles, but we expect that to double next year,” Daniel predicts. Temperature-controlled production rooms with increasing technical details are in operation A few blocks from downtown Allen and the exit to Fernández Oro, corner of Mariani and Alte streets. brown.

Photo: Instagram.

Photo: Instagram.

, while maintaining the same key facts, dates, and quotes. The new text should feel completely fresh, naturally flowing, and as if written from scratch by a professional human news editor.

Retain all people’s declarations in quotation marks (” “) exactly as they appear in

Before the rise of pears and apples, the Alto Valley was land dedicated to growing grapevines.In the early 20th century, breweries proliferated in every town. Coopermaking was a necessary occupation at the time, but The evolution of the industry makes it disappear.

“Until the 1960s, the most common continental What is used to transport wine? This is called “Poldelez” (commonly known as “bordalesa”) has about 180 or 200 liters. With the movement of loading and unloading, in addition to the transfer of trucks or train cars, The stick is loose [maderas] This causes it to start leaking Therefore, the cooper’s main job is to dismantle the Bordeaux and restore its use by inserting reed leaves between the staves. that job This is called “caulking”.

“All wineries, depending on the amount of wine they produce, have one, two, three or more coopers,” he said. Engineer and teacher Federico WitkowskiDedicated to restoring the history of dozens of wineries, on its Facebook page “Poster for Bordeaux wines from northern Patagonia.”

Part of the Bodega Canale Archives – Photo: Juan Thomes.

Part of the Bodega Canale Archives – Photo: Juan Thomes.

***

Antonio Campos is one of the Coopers, “Campito” His neighbors called him this. There aren’t many of these craftsmen, so they become experts in their fields and are therefore in high demand.. The iconic “Baron Rio Negro”, The second phase of the groundbreaking “Los Viñedos” existed before Allen founded it, and he was one of the company’s employees. Every morning, his children would set off on his red bicycle Complete a shift at a property currently operating in a local industrial parkLocated next to Cunmalleu Ceramics in Biló Access.

Neuquino de la Confluencia, born 1913returning each afternoon to continue processing some specific requests, in this case with homemade winehe solved the problem in a studio he set up in his home. “They have never Allen, Fernández Oro and Guerrico’s farmswith big trucks and vans,” recalled his daughter Lydia. Antonio’s first experience working in a production area was on the land owned by the family of Manuel Mir, also in Allen, who also ran a winery there.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.***

Photo: Facebook “Boldelei Poster…”

Photo: Facebook “Boldelei Poster…”***

In Roca, coopers had a similar experience; They worked on the centenary production of Humberto Canale, As its brand says, it’s been in effect since 1909. Very similar to the scene seen in “Campito” Every day: huge barrels with a capacity of over 27,000 liters, made of high-quality wood Oak from the Nancy region of Francethose things that shelter the expected grape fruit.

Today’s natural containers, They have not been used in at least 15 years., But it still needs to be kept moistso they don’t dry out and ruin the perfect fit that’s kept them assembled for nearly a century. “They are only cleaned with pressurized water, without any cleaning products,” he stressed. Horacio Bibiloni, corporate winemakertalk to RÍO Negro.

Photo: Juan Tomes.

Photo: Juan Tomes. ***

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In front of those huge wooden barrels, Accessories such as curtains are displayed on the walls.a French term referring to the “valve” used to empty the contents after the aging process. The seal on the cover faces people who stop to admire it. It still displays its French origins as a brand as a guarantee of quality.

Although the coopers require manual, patient, and precise work, it is important to note that none of these barrels are made or shaped in Argentina, but rather shipped from Europe and then assembled at their final destination. This kind of logistics leads to Maintain a service life of at least several decadesas far as Canale is concerned, continuity is through Two workers, working together to maintain 100 of these giants. At the same time, Bordeaux wine barrels, also known today as “casks”, appeared, which were of smaller capacity and were used for transportation and sales.

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In this case, Witkovsky raised this question: why they disappeared Mr. and Mrs. Cooper when? “Beginning in the late 1960s and early 1970s, the National Institute of Viticulture (INV) issued a resolution Distribution of famous “loose wine” banned in Bordeaux” said the expert. “The operation of these vessels consisted of placing them horizontally, inserting a wooden spigot called a spigot, and punching a hole in the top slat so that air could enter and the wine could drain out easily. The vent is then covered with a dowel, also made of wood, called an “espiche”,” he added.

Health measures mandate use of glass for half johns and bottles, forcing winemakers to make changes Integrated washing machinery The quantity of these containers exceeds economic possibilities, especially for the smallest producers. “this produce closure Many institutions because they cannot afford these costs,” the engineer added.

Photo: The Allen Project.

Photo: The Allen Project.***

Therefore, Antonio’s profession is losing demand which forces him to retire while In addition to the “garzador”, there are also tools such as the “garlopa” (planer), hammer and “chazo” for lowering the hoop (metal ring). Today, work similar to what he did is carried out in Canale, for example, by two trained operators, since this is mass production, but they are not classified as coopers. “Currently, there is a trend towards using oak containers again, with larger capacities, we are talking about 6800 liters, and the life of these oak barrels will be longer, so maybe after a while we will have to restore this digital cooper ,” Bibiloni admitted.

Meanwhile, Allen launched an initiative Seeking limited work, betting on the organic and artisanal, makes Daniel González and his team “Juan de Ferena” will be trained in knowledge that seems dormant.. As owners of the González Acuña family winery, they are responsible for restoring Second-use barrels, brought into the country Importers in Mendoza and Buenos Aires have been aging their products for four years, but have only registered the trademark for one.

Photo: Instagram.

Photo: Instagram.***

In this context It’s hard to get the same tools as last yearDaniel and his people managed to find alternatives among the current options and achieve the same results. Do not leave residue on the wood, do not use glue and disinfect These are the prerequisites to avoid contaminating the wine, so the rest comes down to perseverance and curiosity.

As if time has never passed, Reed rods continue to be an ally in ensuring airtightness Between the “staff”, through Steam, ozone gas and sulfuranother original resource that has received a lot of attention. “We do all the work by hand and after the fermentation tanks are produced Once in barrel, it can be stored for 12 months, 18 months and up to 24 months. Our annual production is about 3,000 bottles, but we expect that to double next year,” Daniel predicts. Temperature-controlled production rooms with increasing technical details are in operation A few blocks from downtown Allen and the exit to Fernández Oro, corner of Mariani and Alte streets. brown.

Photo: Instagram.

Photo: Instagram.

, incorporating them naturally into the rewritten text.

Preserve all original HTML tags from

Before the rise of pears and apples, the Alto Valley was land dedicated to growing grapevines.In the early 20th century, breweries proliferated in every town. Coopermaking was a necessary occupation at the time, but The evolution of the industry makes it disappear.

“Until the 1960s, the most common continental What is used to transport wine? This is called “Poldelez” (commonly known as “bordalesa”) has about 180 or 200 liters. With the movement of loading and unloading, in addition to the transfer of trucks or train cars, The stick is loose [maderas] This causes it to start leaking Therefore, the cooper’s main job is to dismantle the Bordeaux and restore its use by inserting reed leaves between the staves. that job This is called “caulking”.

“All wineries, depending on the amount of wine they produce, have one, two, three or more coopers,” he said. Engineer and teacher Federico WitkowskiDedicated to restoring the history of dozens of wineries, on its Facebook page “Poster for Bordeaux wines from northern Patagonia.”

Part of the Bodega Canale Archives – Photo: Juan Thomes.

Part of the Bodega Canale Archives – Photo: Juan Thomes.

***

Antonio Campos is one of the Coopers, “Campito” His neighbors called him this. There aren’t many of these craftsmen, so they become experts in their fields and are therefore in high demand.. The iconic “Baron Rio Negro”, The second phase of the groundbreaking “Los Viñedos” existed before Allen founded it, and he was one of the company’s employees. Every morning, his children would set off on his red bicycle Complete a shift at a property currently operating in a local industrial parkLocated next to Cunmalleu Ceramics in Biló Access.

Neuquino de la Confluencia, born 1913returning each afternoon to continue processing some specific requests, in this case with homemade winehe solved the problem in a studio he set up in his home. “They have never Allen, Fernández Oro and Guerrico’s farmswith big trucks and vans,” recalled his daughter Lydia. Antonio’s first experience working in a production area was on the land owned by the family of Manuel Mir, also in Allen, who also ran a winery there.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.***

Photo: Facebook “Boldelei Poster…”

Photo: Facebook “Boldelei Poster…”***

In Roca, coopers had a similar experience; They worked on the centenary production of Humberto Canale, As its brand says, it’s been in effect since 1909. Very similar to the scene seen in “Campito” Every day: huge barrels with a capacity of over 27,000 liters, made of high-quality wood Oak from the Nancy region of Francethose things that shelter the expected grape fruit.

Today’s natural containers, They have not been used in at least 15 years., But it still needs to be kept moistso they don’t dry out and ruin the perfect fit that’s kept them assembled for nearly a century. “They are only cleaned with pressurized water, without any cleaning products,” he stressed. Horacio Bibiloni, corporate winemakertalk to RÍO Negro.

Photo: Juan Tomes.

Photo: Juan Tomes. ***

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In front of those huge wooden barrels, Accessories such as curtains are displayed on the walls.a French term referring to the “valve” used to empty the contents after the aging process. The seal on the cover faces people who stop to admire it. It still displays its French origins as a brand as a guarantee of quality.

Although the coopers require manual, patient, and precise work, it is important to note that none of these barrels are made or shaped in Argentina, but rather shipped from Europe and then assembled at their final destination. This kind of logistics leads to Maintain a service life of at least several decadesas far as Canale is concerned, continuity is through Two workers, working together to maintain 100 of these giants. At the same time, Bordeaux wine barrels, also known today as “casks”, appeared, which were of smaller capacity and were used for transportation and sales.

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In this case, Witkovsky raised this question: why they disappeared Mr. and Mrs. Cooper when? “Beginning in the late 1960s and early 1970s, the National Institute of Viticulture (INV) issued a resolution Distribution of famous “loose wine” banned in Bordeaux” said the expert. “The operation of these vessels consisted of placing them horizontally, inserting a wooden spigot called a spigot, and punching a hole in the top slat so that air could enter and the wine could drain out easily. The vent is then covered with a dowel, also made of wood, called an “espiche”,” he added.

Health measures mandate use of glass for half johns and bottles, forcing winemakers to make changes Integrated washing machinery The quantity of these containers exceeds economic possibilities, especially for the smallest producers. “this produce closure Many institutions because they cannot afford these costs,” the engineer added.

Photo: The Allen Project.

Photo: The Allen Project.***

Therefore, Antonio’s profession is losing demand which forces him to retire while In addition to the “garzador”, there are also tools such as the “garlopa” (planer), hammer and “chazo” for lowering the hoop (metal ring). Today, work similar to what he did is carried out in Canale, for example, by two trained operators, since this is mass production, but they are not classified as coopers. “Currently, there is a trend towards using oak containers again, with larger capacities, we are talking about 6800 liters, and the life of these oak barrels will be longer, so maybe after a while we will have to restore this digital cooper ,” Bibiloni admitted.

Meanwhile, Allen launched an initiative Seeking limited work, betting on the organic and artisanal, makes Daniel González and his team “Juan de Ferena” will be trained in knowledge that seems dormant.. As owners of the González Acuña family winery, they are responsible for restoring Second-use barrels, brought into the country Importers in Mendoza and Buenos Aires have been aging their products for four years, but have only registered the trademark for one.

Photo: Instagram.

Photo: Instagram.***

In this context It’s hard to get the same tools as last yearDaniel and his people managed to find alternatives among the current options and achieve the same results. Do not leave residue on the wood, do not use glue and disinfect These are the prerequisites to avoid contaminating the wine, so the rest comes down to perseverance and curiosity.

As if time has never passed, Reed rods continue to be an ally in ensuring airtightness Between the “staff”, through Steam, ozone gas and sulfuranother original resource that has received a lot of attention. “We do all the work by hand and after the fermentation tanks are produced Once in barrel, it can be stored for 12 months, 18 months and up to 24 months. Our annual production is about 3,000 bottles, but we expect that to double next year,” Daniel predicts. Temperature-controlled production rooms with increasing technical details are in operation A few blocks from downtown Allen and the exit to Fernández Oro, corner of Mariani and Alte streets. brown.

Photo: Instagram.

Photo: Instagram.

, including those for images, photos, videos, embeds (e.g., Instagram, X/Twitter), and other multimedia elements, and ensure they are correctly positioned in the rewritten article.

Write with a human-like tone and style, avoiding repetitive phrasing, robotic patterns, or overly formal language. Use creative yet professional language, focusing on engaging and authentic storytelling.

Follow Associated Press (AP) guidelines for style, clarity, and professionalism, including proper use of numbers, punctuation, and attribution.

Be optimized for SEO, using structured HTML tags (H1, H2, H3) and adhering to Google’s E-E-A-T standards. Write a new, keyword-optimized headline that feels natural and engaging.

Exclude all references to the original source or publication, ensuring no identifiable details about

Before the rise of pears and apples, the Alto Valley was land dedicated to growing grapevines.In the early 20th century, breweries proliferated in every town. Coopermaking was a necessary occupation at the time, but The evolution of the industry makes it disappear.

“Until the 1960s, the most common continental What is used to transport wine? This is called “Poldelez” (commonly known as “bordalesa”) has about 180 or 200 liters. With the movement of loading and unloading, in addition to the transfer of trucks or train cars, The stick is loose [maderas] This causes it to start leaking Therefore, the cooper’s main job is to dismantle the Bordeaux and restore its use by inserting reed leaves between the staves. that job This is called “caulking”.

“All wineries, depending on the amount of wine they produce, have one, two, three or more coopers,” he said. Engineer and teacher Federico WitkowskiDedicated to restoring the history of dozens of wineries, on its Facebook page “Poster for Bordeaux wines from northern Patagonia.”

Part of the Bodega Canale Archives – Photo: Juan Thomes.

Part of the Bodega Canale Archives – Photo: Juan Thomes.

***

Antonio Campos is one of the Coopers, “Campito” His neighbors called him this. There aren’t many of these craftsmen, so they become experts in their fields and are therefore in high demand.. The iconic “Baron Rio Negro”, The second phase of the groundbreaking “Los Viñedos” existed before Allen founded it, and he was one of the company’s employees. Every morning, his children would set off on his red bicycle Complete a shift at a property currently operating in a local industrial parkLocated next to Cunmalleu Ceramics in Biló Access.

Neuquino de la Confluencia, born 1913returning each afternoon to continue processing some specific requests, in this case with homemade winehe solved the problem in a studio he set up in his home. “They have never Allen, Fernández Oro and Guerrico’s farmswith big trucks and vans,” recalled his daughter Lydia. Antonio’s first experience working in a production area was on the land owned by the family of Manuel Mir, also in Allen, who also ran a winery there.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.

Antonio’s old enlistment manual is a souvenir of his years in “Baliani”.***

Photo: Facebook “Boldelei Poster…”

Photo: Facebook “Boldelei Poster…”***

In Roca, coopers had a similar experience; They worked on the centenary production of Humberto Canale, As its brand says, it’s been in effect since 1909. Very similar to the scene seen in “Campito” Every day: huge barrels with a capacity of over 27,000 liters, made of high-quality wood Oak from the Nancy region of Francethose things that shelter the expected grape fruit.

Today’s natural containers, They have not been used in at least 15 years., But it still needs to be kept moistso they don’t dry out and ruin the perfect fit that’s kept them assembled for nearly a century. “They are only cleaned with pressurized water, without any cleaning products,” he stressed. Horacio Bibiloni, corporate winemakertalk to RÍO Negro.

Photo: Juan Tomes.

Photo: Juan Tomes. ***

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In front of those huge wooden barrels, Accessories such as curtains are displayed on the walls.a French term referring to the “valve” used to empty the contents after the aging process. The seal on the cover faces people who stop to admire it. It still displays its French origins as a brand as a guarantee of quality.

Although the coopers require manual, patient, and precise work, it is important to note that none of these barrels are made or shaped in Argentina, but rather shipped from Europe and then assembled at their final destination. This kind of logistics leads to Maintain a service life of at least several decadesas far as Canale is concerned, continuity is through Two workers, working together to maintain 100 of these giants. At the same time, Bordeaux wine barrels, also known today as “casks”, appeared, which were of smaller capacity and were used for transportation and sales.

Photo: Facebook Humberto Canale.

Photo: Facebook Humberto Canale.***

In this case, Witkovsky raised this question: why they disappeared Mr. and Mrs. Cooper when? “Beginning in the late 1960s and early 1970s, the National Institute of Viticulture (INV) issued a resolution Distribution of famous “loose wine” banned in Bordeaux” said the expert. “The operation of these vessels consisted of placing them horizontally, inserting a wooden spigot called a spigot, and punching a hole in the top slat so that air could enter and the wine could drain out easily. The vent is then covered with a dowel, also made of wood, called an “espiche”,” he added.

Health measures mandate use of glass for half johns and bottles, forcing winemakers to make changes Integrated washing machinery The quantity of these containers exceeds economic possibilities, especially for the smallest producers. “this produce closure Many institutions because they cannot afford these costs,” the engineer added.

Photo: The Allen Project.

Photo: The Allen Project.***

Therefore, Antonio’s profession is losing demand which forces him to retire while In addition to the “garzador”, there are also tools such as the “garlopa” (planer), hammer and “chazo” for lowering the hoop (metal ring). Today, work similar to what he did is carried out in Canale, for example, by two trained operators, since this is mass production, but they are not classified as coopers. “Currently, there is a trend towards using oak containers again, with larger capacities, we are talking about 6800 liters, and the life of these oak barrels will be longer, so maybe after a while we will have to restore this digital cooper ,” Bibiloni admitted.

Meanwhile, Allen launched an initiative Seeking limited work, betting on the organic and artisanal, makes Daniel González and his team “Juan de Ferena” will be trained in knowledge that seems dormant.. As owners of the González Acuña family winery, they are responsible for restoring Second-use barrels, brought into the country Importers in Mendoza and Buenos Aires have been aging their products for four years, but have only registered the trademark for one.

Photo: Instagram.

Photo: Instagram.***

In this context It’s hard to get the same tools as last yearDaniel and his people managed to find alternatives among the current options and achieve the same results. Do not leave residue on the wood, do not use glue and disinfect These are the prerequisites to avoid contaminating the wine, so the rest comes down to perseverance and curiosity.

As if time has never passed, Reed rods continue to be an ally in ensuring airtightness Between the “staff”, through Steam, ozone gas and sulfuranother original resource that has received a lot of attention. “We do all the work by hand and after the fermentation tanks are produced Once in barrel, it can be stored for 12 months, 18 months and up to 24 months. Our annual production is about 3,000 bottles, but we expect that to double next year,” Daniel predicts. Temperature-controlled production rooms with increasing technical details are in operation A few blocks from downtown Allen and the exit to Fernández Oro, corner of Mariani and Alte streets. brown.

Photo: Instagram.

Photo: Instagram.

remain.

Be between 800–1,200 words long, with clear subheadings for readability.

Provide only the final rewritten article text with all original HTML tags properly retained and integrated. Ensure the content reads naturally, as if written by a skilled human journalist, with no robotic tone or AI-like repetition. Do not include any notes, explanations, or commentary.

Are there any contemporary examples of renewed interest in artisanal barrel-making?

The provided text discusses the disappearing craft of “wine coopers” – specialists who build and maintain large oak barrels used for aging wine. It mentions a specific example in Argentina, where two coopers at the Canale winery maintain 100 large barrels, highlighting the manual and meticulous nature of the work.

The decline of coopers is attributed to several factors:

* **Health regulations:** The shift towards using glass bottles and the need for mechanized cleaning processes made traditional wooden barrels less appealing.

* **Cost:** Mass production favored larger, more economical containers, making handcrafted wooden barrels less cost-effective.

* **Availability of pre-made barrels:** Ordering ready-made barrels from Europe proved more practical than employing skilled coopers to build them locally.

* **Rarity of materials and expertise:**

The scarcity of skilled coopers and the tools needed to practice the craft contributes to its decline.

However, there is a renewed interest in artisanal barrel-making, led by individuals like Daniel González of the “Juan de Ferena” winery who are restoring and repurposing used barrels using traditional techniques. This signifies the enduring appeal of the craft alongside the evolution of winemaking practices.