Smartphones, TVs, household appliances, connected objects… electronic devices now populate our daily lives. Their sales volume is soaring, fueled by software or marketing obsolescence that almost all brands promote. At the same time, these devices generate strong impacts on the environment. Energy-intensive for their production or consumption, they are still rarely recycled and reused. And their production conditions are far from always respectful of workers. In short, it is urgent to change the model by working on the circular economy. But obstacles still need to be removed. An update with professionals in the sector*.

Reconditioning as a stepping stone…

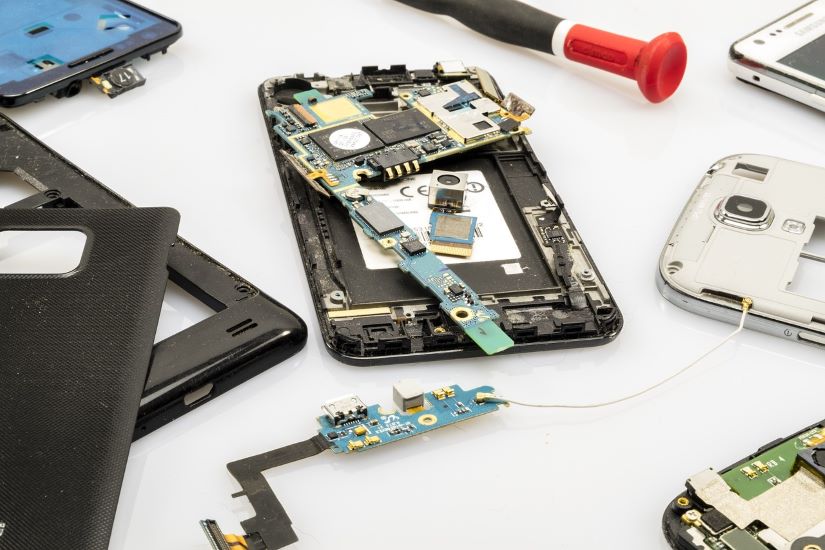

Giving a second life to the product through reconditioning has become common in the mobile phone sector. While only 6 or 7 years ago, this niche accounted for 10% of the market, it has now climbed to 25% (2023). “There is no reason why it should not reach 50% in the coming years, like what is happening in the automobile industry where second-hand cars account for 70% of the market,” hopes Gautier Feld, co-founder of CircularX, a technology platform that supports distributors in the development of the second-hand market. With a significant monetary value, their ease of movement, their organized collection circuit and their lifespan of several years and a strong expectation from consumers for quality products at a lower price, these products are in fact particularly suitable for second-hand.

But while the reconditioning trend is growing, all electrical products are far from being as advanced, due to a lack of collection circuits, perceived value in second-hand or other. However, as professionals point out, reconditioning is actually the easiest step to get your foot in the circular economy. « C“This is an approach that is extremely compatible with the current linear economic model because it takes over part of the classic value chain. Repair is more complicated because the know-how is lost: for 20 to 30 years, the number of repairers has continued to decline”underlines Régis Koenig, the repair and sustainability director of Fnac Darty. However, the need exists: at the European leader in the distribution of household appliances, “7 out of 10 people buy a new device because the previous one broke down, while 95% of devices can still be repaired following 8 years of use”he assures.

Learn more: What is the circular economy?

…but which has its limits

In fact, for some products, the cost of repair is disproportionate compared to buying a new one. This can easily be the case for a washing machine, underlines designer Christopher Santerre, ex-CEO of l’Increvable, an aborted project for an (eco)designed washing machine to last more than 20 years. “Let’s take the case of a machine bearing. The replacement part costs around €2, but on some products it is so difficult to access that it requires half a day’s work, which makes the price of the repair soar to over €300! If the wear is normal, it is not normal that the repair is not the simplest approach.”deplores the eco-design specialist.

Finally, reconditioning or second-hand can also lead to a rebound effect, i.e. the cancellation of positive ecological effects by a shift in consumption and use of this type of product. This is particularly what can be observed in textiles, even if it seems to be less the case in the smartphone market, for example**. “I tend to think that in the electronics market this can drive quality and durability upwards because for it to arrive second-hand, the product still has to have value and we see that today, consumers look at the resale value when purchasing”specifies Gautier Field.

The service model and the extension of the lifespan as a line of sight

To overcome the limits of reconditioned products and get out of the volume model that weighs on resources, it is therefore towards sobriety first but also the extension of the lifespan and the service model that we must turn. This is in particular what Fnac-Darty has been trying for several years. The group has become the leading repairer in France for electronic products with 2,500 technicians and nearly 2.5 million interventions each year. But despite the strengthening of legislation (fight once morest planned obsolescence, repairability index, etc.), all electronic products are still far from being effectively repairable and even less repaired as shown by the latest barometer of the group’s following-sales service. The price of spare parts in particular weighs on certain products such as televisions.

To develop repairs, Fnac-Darty is banking on a subscription system that has won over 1 million customers in 2024. For €12/month, they can have all their electronic devices repaired. This is a substantial investment but it extends the average lifespan of products by 3 to 4 years compared to a traditional customer, avoids greenhouse gas emissions or product extraction, etc. And it also has significant advantages for the distributor, since it increases customer loyalty and the average basket with the purchase of more high-end devices, since they are supposed to last longer.

To go deeper : The failures of the AGEC law

Financing, regulation and desirability: obstacles to overcome in order to change scale

Making the product last a long time, a whole life… that was the goal of the Increvable. A simple but high-end washing machine that never saw the light of day, particularly due to lack of funding. “To work on a high-performance, desirable, easy-to-repair and long-lasting washing machine, the price was around €1,000”underlines Christophe Santerre. A price that some 200 customers who had pre-ordered the machine before it was even built were prepared to pay. But the financing did not follow.

“The problem with hardware is that it costs a lot of money up front, with returns on investment that can be slow.”underlines the former boss of the company which went bankrupt in 2020. “We had raised €200,000 of the more than a million we needed to prove the concept. Investors did not want to take the risk of a 7 or 8 year ROI,” he regrets. The company that was looking to ally itself with a manufacturer to avoid paying the 10 to 15 million euros needed to create its own factory saw its partnership project fail when the manufacturer was bought out by a Chinese competitor…

“This market is far from obvious for new entrants and start-ups because the models of reuse or sustainability are ‘orthogonal’ to the classic linear model and therefore encounter great difficulties.” adds François-Henri Champagne, Early Stage Investment Director at Citizen Capital, an impact investment company. New companies are thus tackling specific barriers such as measuring the impact and profitability of reconditioned products, which investors currently lack to ensure the viability of the project, he believes.

To ensure the profitability and deployment of these models, the regulations also need to be reviewed. Because they still largely favor the linear and volume economy: taxes on raw materials remain low when labor is lower, even though it is an essential part of the circular economy model that promotes the creation of non-relocatable jobs. It also remains to ensure that the desirability of sobriety, repairability or reuse becomes equal to or greater than a state-of-the-art product. We are still far from that. We will also have to work more in ecosystems, a business practice that is still too rarely implemented.

*The comments were collected during a round table organized by EY-Fabernovel

**The second-hand market share is growing but the overall market has been declining for two years, even if experts are counting on a rebound linked in particular to the arrival of AI in new models.

The Circular Economy of Electronic Products: Opportunities and Challenges for a Sustainable Future

Smartphones, TVs, household appliances, connected objects… electronic devices now populate our daily lives. Their sales volume is soaring, boosted by software or marketing obsolescence that almost all brands promote. At the same time, these devices generate strong impacts on the environment. Energy-intensive for their production or consumption, they are still rarely recycled and reused. And their production conditions are far from always respectful of workers. In short, it is urgent to change the model by working on the circular economy. But obstacles still need to be removed. An update with professionals in the sector*.

Reconditioning as a stepping stone…

Giving a second life to the product through reconditioning has become common in the mobile phone sector. While only 6 or 7 years ago, this niche accounted for 10% of the market, it has now climbed to 25% (2023). “There is no reason why it should not reach 50% in the coming years, like what is happening in the automobile industry where second-hand cars account for 70% of the market,” hopes Gautier Feld, co-founder of CircularX, a technology platform that supports distributors in the development of the second-hand market. With a significant monetary value, their ease of movement, their organized collection circuit and their lifespan of several years and a strong expectation from consumers for quality products at a lower price, these products are in fact particularly suitable for second-hand.

But while the reconditioning trend is growing, all electrical products are far from being as advanced, due to a lack of collection circuits, perceived value in second-hand or other. However, as professionals point out, reconditioning is actually the easiest step to get your foot in the circular economy. « C“This is an approach that is extremely compatible with the current linear economic model because it takes over part of the classic value chain. Repair is more complicated because the know-how is lost: for 20 to 30 years, the number of repairers has continued to decline”underlines Régis Koenig, the repair and sustainability director of Fnac Darty. However, the need exists: at the European leader in the distribution of household appliances, “7 out of 10 people buy a new device because the previous one broke down, while 95% of devices can still be repaired following 8 years of use”he assures.

Learn more: What is the circular economy?

…but which has its limits

In fact, for some products, the cost of repair is disproportionate compared to buying a new one. This can easily be the case for a washing machine, underlines designer Christopher Santerre, ex-CEO of l’Increvable, an aborted project for an (eco)designed washing machine to last more than 20 years. “Let’s take the case of a machine bearing. The replacement part costs around €2, but on some products it is so difficult to access that it requires half a day’s work, which makes the price of the repair soar to over €300! If the wear is normal, it is not normal that the repair is not the simplest approach.”deplores the eco-design specialist.

Finally, reconditioning or second-hand can also lead to a rebound effect, i.e. the cancellation of positive ecological effects by a shift in consumption and use of this type of product. This is particularly what can be observed in textiles, even if it seems to be less the case in the smartphone market, for example**. “I tend to think that in the electronics market this can drive quality and durability upwards because for it to arrive second-hand, the product still has to have value and we see that today, consumers look at the resale value when purchasing”specifies Gautier Field.

The service model and the extension of the lifespan as a line of sight

To overcome the limits of reconditioned products and get out of the volume model that weighs on resources, it is therefore towards sobriety first but also the extension of the lifespan and the service model that we must turn. This is in particular what Fnac-Darty has been trying for several years. The group has become the leading repairer in France for electronic products with 2,500 technicians and nearly 2.5 million interventions each year. But despite the strengthening of legislation (fight once morest planned obsolescence, repairability index, etc.), all electronic products are still far from being effectively repairable and even less repaired as shown by the latest barometer of the group’s following-sales service. The price of spare parts in particular weighs on certain products such as televisions.

To develop repairs, Fnac-Darty is banking on a subscription system that has won over 1 million customers in 2024. For €12/month, they can have all their electronic devices repaired. This is a substantial investment but it extends the average lifespan of products by 3 to 4 years compared to a traditional customer, avoids greenhouse gas emissions or product extraction, etc. And it also has significant advantages for the distributor, since it increases customer loyalty and the average basket with the purchase of more high-end devices, since they are supposed to last longer.

To go deeper : The failures of the AGEC law

Financing, regulation and desirability: obstacles to overcome in order to change scale

Making the product last a long time, a whole life… that was the goal of the Increvable. A simple but high-end washing machine that never saw the light of day, particularly due to lack of funding. “To work on a high-performance, desirable, easy-to-repair and long-lasting washing machine, the price was around €1,000”underlines Christophe Santerre. A price that some 200 customers who had pre-ordered the machine before it was even built were prepared to pay. But the financing did not follow.

“The problem with hardware is that it costs a lot of money up front, with returns on investment that can be slow.”underlines the former boss of the company which went bankrupt in 2020. “We had raised €200,000 of the more than a million we needed to prove the concept. Investors did not want to take the risk of a 7 or 8 year ROI,” he regrets. The company that was looking to ally itself with a manufacturer to avoid paying the 10 to 15 million euros needed to create its own factory saw its partnership project fail when the manufacturer was bought out by a Chinese competitor…

“This market is far from obvious for new entrants and start-ups because the models of reuse or sustainability are ‘orthogonal’ to the classic linear model and therefore encounter great difficulties.” adds François-Henri Champagne, Early Stage Investment Director at Citizen Capital, an impact investment company. New companies are thus tackling specific barriers such as measuring the impact and profitability of reconditioned products, which investors currently lack to ensure the viability of the project, he believes.

To ensure the profitability and deployment of these models, the regulations also need to be reviewed. Because they still largely favor the linear and volume economy: taxes on raw materials remain low when labor is lower, even though it is an essential part of the circular economy model that promotes the creation of non-relocatable jobs. It also remains to ensure that the desirability of sobriety, repairability or reuse becomes equal to or greater than a state-of-the-art product. We are still far from that. We will also have to work more in ecosystems, a business practice that is still too rarely implemented.

*The comments were collected during a round table organized by EY-Fabernovel

**The second-hand market share is growing but the overall market has been declining for two years, even if experts are counting on a rebound linked in particular to the arrival of AI in new models.