2023-10-15 10:02:18

Airbus Helicopters has chosen Trumpf for the AM systems in the new AM production center in Donauwürth. The Airbus subsidiary serially prints parts on a TruPrint 3000 for both the experimental helicopter Racer and for the Airbus A320 and A350 passenger aircraft.

3D printing of parts for the new generation of helicopters should contribute to a lighter weight of the aircraft, says Helmut Färber, location manager of Airbus Helicopters in Donauwürth. This ensures lower fuel consumption, lower operating costs and ultimately a reduction in CO2 emissions. The parts are intended for, among other things, Airbus’ high-speed helicopter, the Racer, and both passenger aircraft of parent company Airbus.

Key technology for more sustainable flying

Weight savings through integration of parts

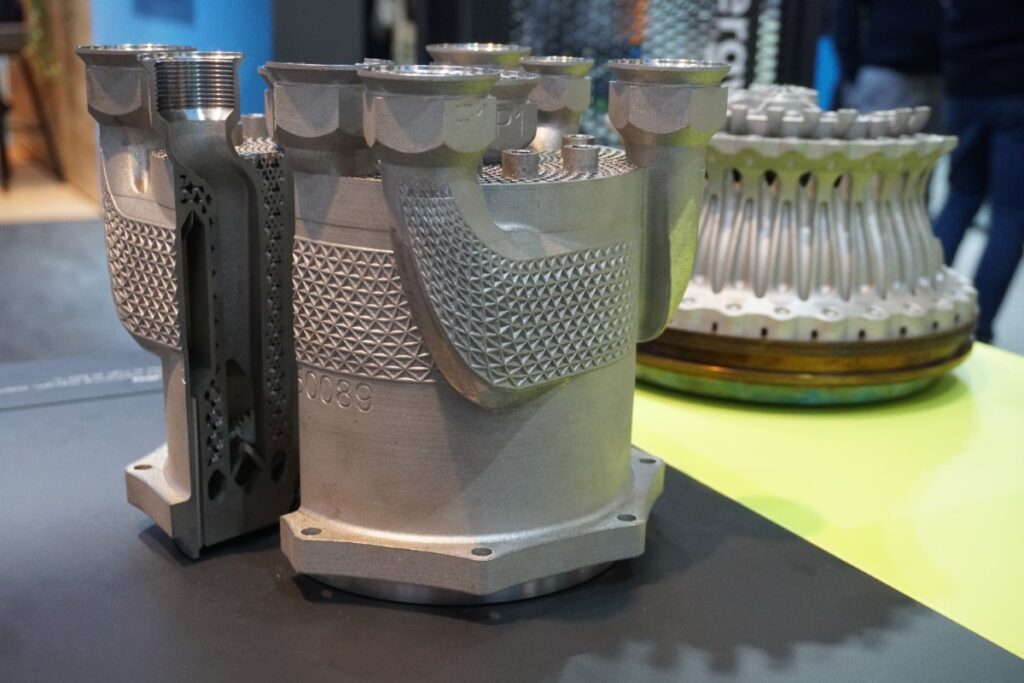

The weight saving is partly because separate parts can be combined into one new part, which is printed in one go in the Trumpf TruPrint metal printer. “Our 3D printing systems are a key technology on the path to sustainable flying and they reduce dependence on long supply chains,” says Richard Bannmüller, CEO TRUMPF Laser and System Technology. The parts that the Airbus subsidiary produces on Trumpf’s AM systems meet the strict requirements of the aviation industry.

Up to 10 times less material required

Produces with Trumpf 3D printers Airbus Helicopters currently structural components for both the helicopter and the A320 and A350 aircraft. The materials are titanium and high-strength aluminum. Compared to the classic machining process for these parts, CNC milling, the aerospace supplier can reduce material consumption by up to a factor of 10 with additive manufacturing. According to Bannmüller, this is also an argument for choosing 3D metal printing over the known production techniques.

1697377764

#Airbus #Helicopters #chooses #TruPrint #series #production