2023-11-07 15:40:40

Valentino Sarapura is five years old today and he is a boy who runs, plays, jumps, goes to the garden and has no health problems. However, when he was a five-month-old baby, his mother Lucila and his father Joaquín noticed that I had something strange on my chest, one side was more swollen than the other, and the first film requested by his pediatrician detected that there was an abnormality in the pulmonary artery. A month later, because the little boy was having trouble breathing and was suffering from repeated infections, they took him to the hospital ward. Norberto Quirno Center for Medical Education and Clinical Research (CEMIC), In Buenos Aires city. There, following several studies, including an endoscopy, they received the precise diagnosis: congenital tracheal stenosis which made it difficult for air to enter and exit the lungs and also, an insufficiency in the development of cartilage in his left lung. The combination of both conditions, something very rare, is dangerous for health because it causes the lung to become continuously inflamed, causes progressive infections and can end in the death of the sufferer.

At the CEMIC they immediately consulted with the pediatric surgeon. Gastón Bellía Munzón from the Pedro de Elizalde Hospital.

“From that moment,” says Valentino’s mother, “ There was a chain of favors from many committed professionals who, without knowing us, got to work with the sole objective of saving our son’s life.”

A precedent in the United States

The surgeon Munzon I had just participated in a medical congress held in Roma and there he learned regarding a surgery carried out in 2013 at the University of Michigan teaching hospital on a pediatric patient whose case was similar to that of Valentino. At that university, a roller-shaped biodegradable exoskeleton had been placed in the baby’s bronchus that facilitated the entry and exit of air. It was the only surgical history known in similar cases.

Munzón began to research more on the subject, looking for written material, He spoke with his team and decided to propose to Valentino’s mother and father repeat the same type of intervention. He explained to them what the surgery entailed, what the risks would be and they, despite all their doubts and fears, gave consent to go ahead. “There was no other option. “Valentino was going to die”clarifies the father.

Who might manufacture a roller-shaped piece in 3D?

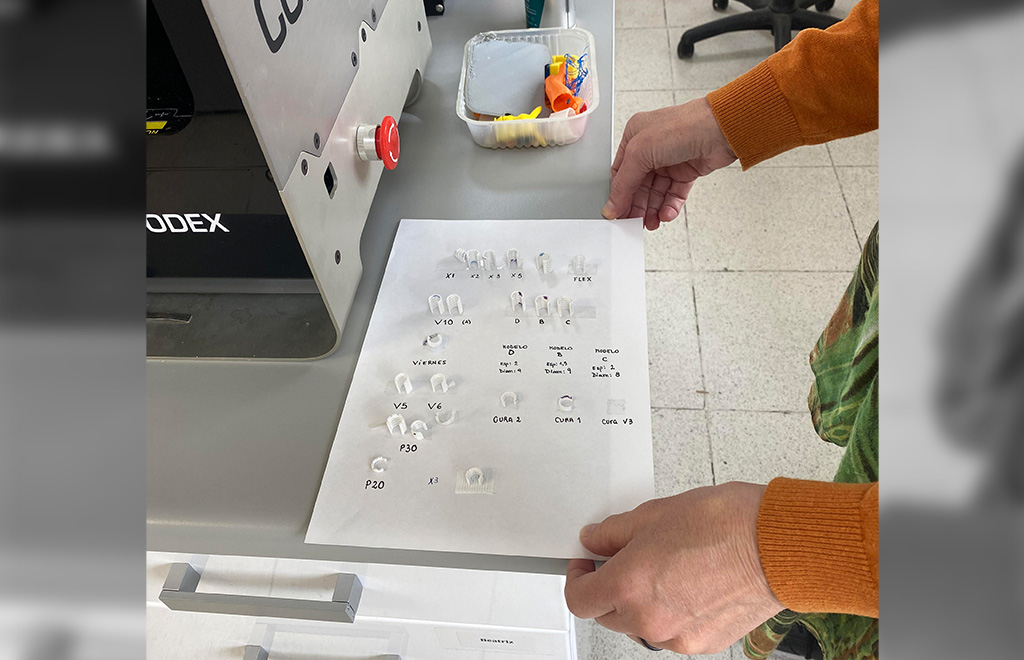

At that moment, an incessant search began on the part of the surgeon and the doctors who accompanied him to find who might manufacturing that key piece that had to have the shape of an open roller with several holes, which had to measure 8 mm in diameter by 20 mm in length. They called several medical supply companies and asked among the industrial designers who was in a position to make that millimetric biodegradable body in record time. The plan was the following: Place this C-shaped structure hugging the bronchus and through the holes in the piece, the surgeon would pass several suture threads to tighten the exoskeleton. In this way, two things would be achieved: open the airway and at the same time support the wall of the bronchus until the tissue itself fibrosed and allowed air to pass through once the exoskeleton (the roller with holes) had biodegraded. .

Lab3Bio

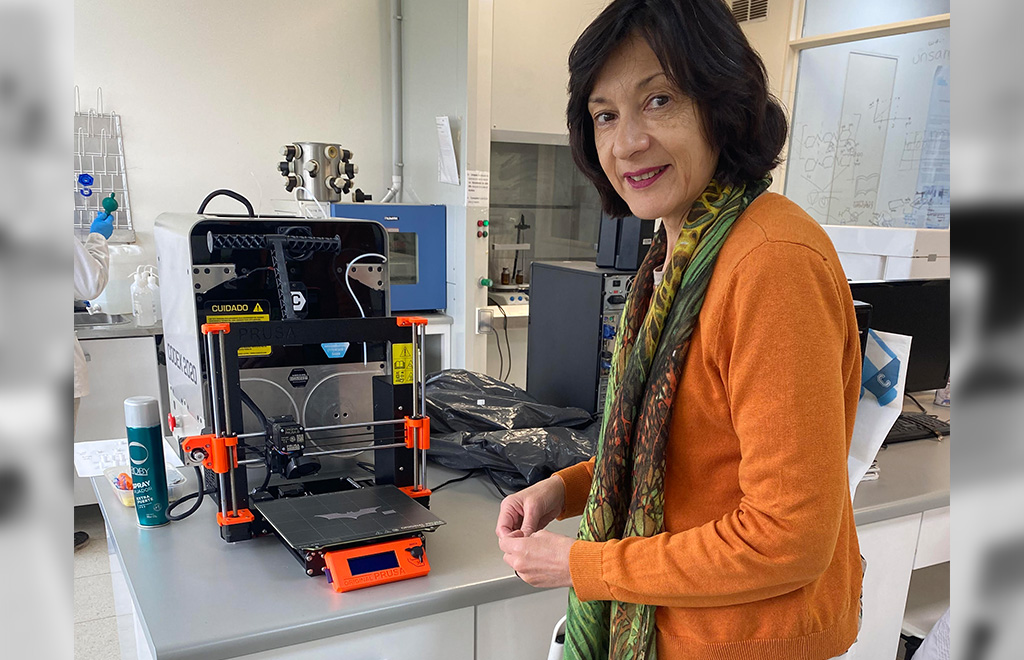

On July 16, 2019, a month following the diagnosis, the phone rang in the laboratory of the University of San Martín (Lab3Bio). Who answered the call The director of the place was the physics researcher Élida Hermida. When she heard Valentino’s story she immediately met with her team to agree on the capabilities and technology. The ones they had might produce the part required for the surgery: the answer was a resounding yes. They had just a few weeks to develop this biodegradable structure. Valentino’s condition worsened day by day, by that time he was already sedated with mechanical respiratory assistance.

The piece that had to be reproduced had to be made of a type of plastic material that would take at least three years to biodegrade, time necessary for Valentino’s own tissue to recover and also required the ability to expand, something essential to accompany the growth of the baby. This material known as polycaprolactone for medical use was not available in Argentina. It was Munzón’s medical team who was in charge of purchasing it abroad and importing it immediately so that it would arrive at UNSAM (University of San Martín) in a few days.

Another challenge to overcome was that the printer they had might print an exoskeleton with the same characteristics and qualities that appeared in the surgery carried out in Michigan.n. At the American university they had used a laser printer that melted material into powder and cost around $300,000. The one in the UNSAM laboratory did not have the same characteristics.

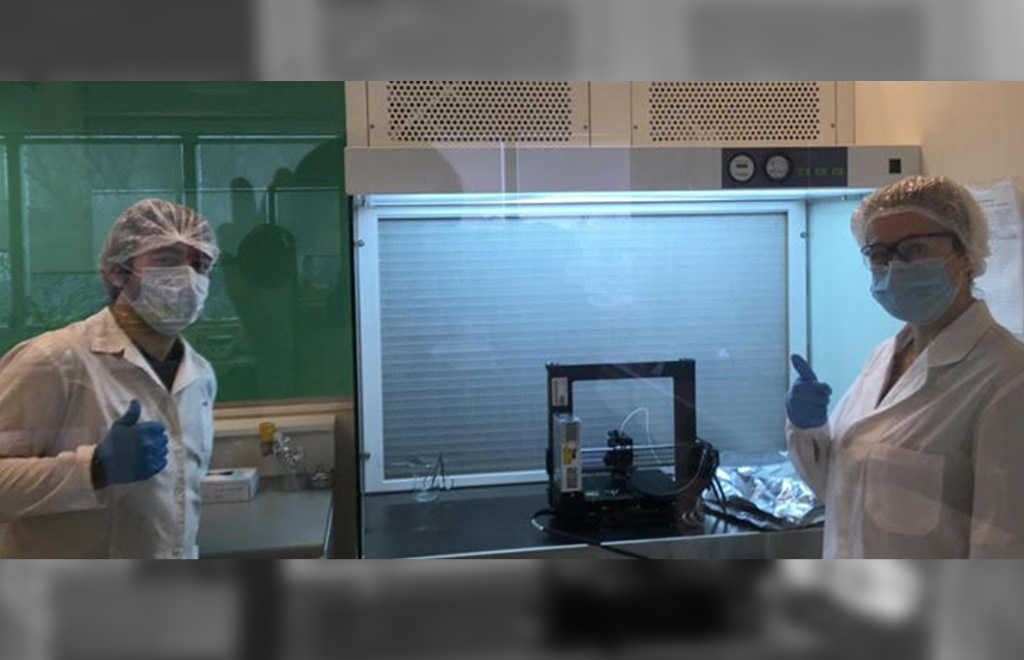

Beatriz Aráoz, doctor in Chemistry, researcher at Lab3Bio, recalled that a colleague, Juan Ignacio Bousquet, a specialist in 3D animation, had a printer — valued at $1,000.ares—that might help you. Aráoz called him, informed him of the situation and Bousquet without hesitation took his printer to the laboratory and joined the project to try to save this baby’s life.

Aráoz and Bousquet say that they worked non-stop for five weeksanas. Everyone was convinced that the solution had to come from there. During the day they tried printing various samples and at night they continued from home reading papers and looking for information to try something new the next day. Thus, they managed to print regarding 50 exoskeletons of different shapes and resolutions and around 100 specific parts. The surgeon in turn needed to have 3D pieces to train his hands; He had to practice how he would make the sutures in that millimeter size, how much time the whole process would take. “It was accelerated learning for everyone with a happy ending. Being able to materialize the idea was fantastic,” says Aráoz, whose work as a researcher is the manufacture of resorbable substrates for bone regeneration.

Hermida adds that all of this would not have been possible if UNSAM had not had the biomaterials laboratory.which has been operating since 2016, thanks to a subsidy that the State granted at the end of 2013 to equip it and train professionals who were able to manufacture something so specific that it saved the life of a child.

Once the perfect structure was achieved, it was time for surgery: It took place on August 21, 2019 at the CEMIC and was a success. Twenty days later, the patient was discharged without suffering any complications.

Another notable innovation from the Lab3bio team was the way they chose to sterilize the product that was placed outside the baby’s bronchus. “Unlike what had been done in the Michigan surgery, in which ethylene oxide was used, here we proposed doing it with gamma radiation, thanks to the knowledge we had from having worked at the Atomic Energy Commission,” explains Hermida. .

Surgery and replicable procedures

Four years later, this story spreads, since the work was published in a scientific journal. Why now and not at the time of surgery?

“Because we wanted to follow up with laryngoscopies to see how the child’s trachea was evolving and how open the airway was,” says Hermida. After surgery, every six months Valentino was monitored through CT scans to see the performance of his lungs. When the presence of the exoskeleton was no longer visible, his bronchus was perfect.

In all the time that has passed, Valentino never needed medicationon (except when he was sedated before the operation) and did not have respiratory tract infections, even having to go through the pandemic. After 34 months, he had his last checkup and his exoskeleton had completely disappeared.

The UNSAM laboratory team then decided to publish the entire detailed clinical case.or, from the symptoms that the pediatric patient had, the diagnosis, type of surgery, plus the research carried out on materials engineering to manufacture the 3D part. Thus, medical and biomedical engineering professionals can access this knowledge and perform similar procedures. Something very useful, especially for those who are in places that cannot access very expensive technologies, says Hermida.

The work can be read in detail in the scientific paper under the title: “Advantages of FDM and gamma irradiation to manufacture personalized medical devices for airway obstructions”.

For his part, Munzón highlights the medical achievement of the intervention: “This operation set a precedent. Valentino was the beginning and now there are two more in Argentina operated with this technique.”

In the United States, from 2012 to 2019, 18 patients were operated on with the technique created by Professor Green of the University of Michigan, of which 15 died. In China there were another 19 cases operated on with a technique similar to that used in the US and the work was only known in 2022.

This content was originally published in RED/ACCION and is republished as part of the ‘Human Journalism’ program, an alliance for quality journalism between RÍO NEGRO and RED/ACCION

1699372185

#clock #Argentine #researchers #manufactured #biodegradable #piece #saved #life #baby #technique #exported #world

:strip_icc()/i.s3.glbimg.com/v1/AUTH_da025474c0c44edd99332dddb09cabe8/internal_photos/bs/2025/O/t/pYxRYmS9Ceq0T5TzAYCg/109707244-brazils-joao-fonseca-reacts-after-a-point-against-italys-lorenzo-sonego-during-their.jpg)