2023-09-04 14:21:49

Of the 100,000 parts that Festo Fast Factory produced last year, regarding 40,000 were 3D printed. Many end parts included. Additive manufacturing is becoming an increasingly important production technology for the drive and automation group, which is already a better solution than conventional techniques for a number of applications.

There are regarding 40 3D printers at Festo worldwide. SLS, Multijet Fusion, FDM and others including Laser Powderbed Fusion for metal. Festo falls back on external service companies for other techniques or specific materials. “For the future, we see many opportunities for the use of additive manufacturing,” says Dieter Fetzer, Head of Prototyping, which includes additive manufacturing. The AM group within Festo Fast Factory acts as an internal 3D printing service provider.

If we can industrialize the process, the technology will become more cost efficient

Small series viable

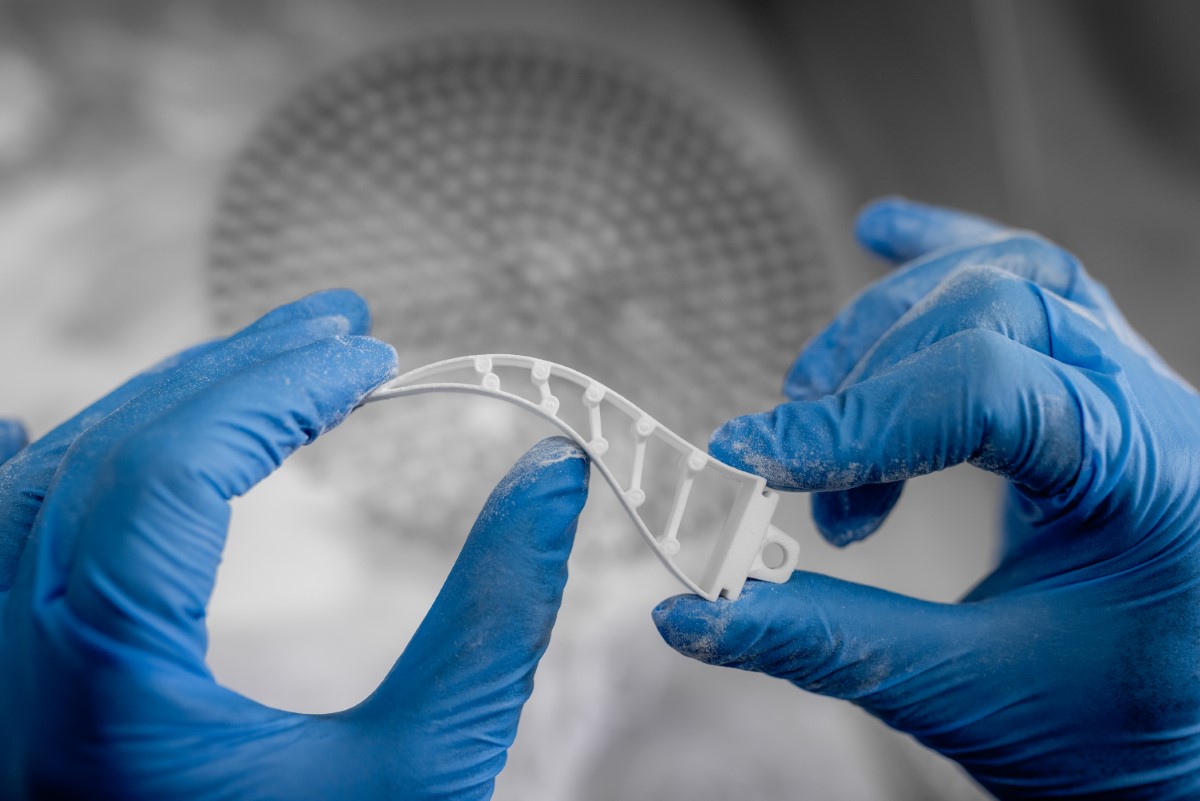

The 40,000 parts show that Festo has long passed the stage of printing prototypes. That is still an important application, says Mattias-Manuel Speckle, Head of Additive Manufacturing Prototyping. This accelerates product development, especially now that Festo is using SLS technology for plastics and parts for functional testing can be quickly made together with 3D metal printing. Even parts that are tested under real conditions. But Festo is mainly concerned with the step towards printing parts for end applications. “3D printing makes smaller series production viable,” says Speckle. In his hands he holds a cable clamp system, the first end application at Festo, 3D printed in PA12. “We need several hundred parts per year. In the past, such a thing was not feasible; too little to make a tool.” Now the parts are 3D printed. The group now has several SLS printers and the factory in Scharnhausen also has a Multijet Fusion.

Tailor-made solutions for customers

An ordinary series at Festo easily means one million components per year. These are numbers for which it pays to invest in tools, such as injection molding or extrusion molds. 3D printing is only a viable way of mass production if the parts add value through intelligent additive design and the industrial concept is optimized, Steffen Trumpheller emphasizes. If you have to make several hundred parts per year, 3D printing can be cheaper. He shows a plastic part with a brush integrated at the end. The part is used in a special electronics environment. About 100 parts are needed per year for this very specific application. “We print them on demand. We print other parts, such as housings, in series and keep them in stock.” Smaller batches can be 3D printed cheaper and faster than with traditional techniques. Additive manufacturing makes it easier for Festo to create custom solutions for very specific applications. The flexibility that 3D printing offers for this is gaining in importance, says Dieter Fetzer.

Arguments for AM

He lists a few other reasons why Festo uses additive manufacturing as a production technique. Producing lighter parts, saving material, integrating functions or covering supply chain risks or solving delivery problems. Starting up a new product so that it is already available before mass production has started. For example, there are countless arguments in favor of additive manufacturing. Mattias-Manuel Speckle shows another part: compressed air flows through the metal part to drive a rotary table. Eight channels run through it. The part, which exists in 3 variants, used to be an extrusion part. Nowadays, Festo 3D prints on a new generation of selective laser melting machines. More than 100 parts fit in one batch. AM is a much more flexible solution than purchasing extruded parts. “Then we are obliged to purchase a minimum number of meters of extrusion profile. Now we print the parts we need.” Several post-processing steps are required, but less than for the extrusion profiles. The roughness of the internal channels does not interfere with the function of the part. In fact, by 3D printing the parts redesigned for AM, 20% more compressed air can be passed through. Thus, the performance of the entire system improves. Festo also needs several hundred of this part every year. “The numbers are increasing every year.”

Stumbling block: insufficiently industrial

Festo’s AM team would like to print even more and expects this to happen in the coming years. The technology roadmap provides for this. The stumbling block at the moment is that AM is not yet an industrial process, says Dieter Fetzer. “The workflow is still largely manual, before and following printing. If we can industrialize the process, the technology will become more cost-efficient.” No matter how digital the AM process itself is, the steps before and following, pre- and post-processing, are still insufficiently industrialized. Fetzer: “The main obstacle is that so much manpower is required between the steps.” Moreover, the printing process itself is also too dependent on the individual operator. It is not consistent enough, says Florèn van Olden. “I know 3D printers of which the operator says: these are my favorite settings. That is not an industrial approach.” The Dutchman works as a Market and Technology Development Manager and is involved, among other things, in selling Festo components to the 3D printer manufacturers themselves.

Qualification

Is sustainability a reason to start 3D printing more in the near future? Less material consumption, production closer to the end customer? Dieter Fetzer says that producing closer to the end customer to avoid supply chain problems additive manufacturing will certainly help. This is quite conceivable for service parts; or for parts that are less common. Or in the run-up to a new product. One point, however, is the qualification. “We have qualification processes for all products. If you change the production technique, you have to re-qualify the product.” These are extra costs and extra time that the group then has to invest in a product.

Ultimately, Mattias-Manuel Speckle points out, it comes down to cost if one of the other arguments for 3D printing is not the deciding factor. “The customer must be willing to pay the price for the part. Then you come back to the numbers.” Party is looking at other, newer 3D printing techniques because of the high volumes. The challenge remains, says Florèn van Olden, to find the best technology for every application. “We are not throwing away the other techniques; we are not going to 3D print everything. But it is becoming more and more a production technology.”

This article appears in the Fall issue of Solutions Magazine. Click here for the whole magazine to read.

URL Copied

1693844909

#Additive #Manufacturing #Festo #increasingly #production #technology