Innovation thrives when affordability meets functionality. Researchers from the University of Strathclyde in Glasgow have pioneered a fully 3D-printed microscope designed for histological imaging. This groundbreaking device, built on an open-source framework from OpenFlexure, combines 3D-printed mechanical and optical components with a Raspberry Pi for control, an LED light source, and a budget-amiable camera. Remarkably, this microscope weighs just 3 kg, can be assembled in under 3 hours, and costs a fraction of conventional models. This offers a significant reduction in cost and complexity, making high-quality microscopy accessible to more users.

The Impact of 3D-Printed Optics on accessibility

This project’s success relies on the use of 3D-printed lenses, developed with an Elegoo resin printer.Professor Gail McConnell, a prominent figure in Bio-photonics at the University, highlighted the transformative impact of this innovation.She stated, “Our team previously developed a method for 3D printing microscope lenses, a pivotal advancement that enabled this breakthrough.” This remark underscores the iterative progress in 3D printing optics, which has now culminated in a fully 3D-printed microscope.

This innovation promises to democratize access to high-quality microscopy, making it feasible for educational institutions, remote labs, and even hobbyists. The combination of affordability, rapid assembly, and modular design opens new doors for scientific exploration and education.

Revolutionizing Microscopy: 3D Printed Lenses Deliver High-Performance Imaging at a Fraction of the Cost

Table of Contents

- 1. Revolutionizing Microscopy: 3D Printed Lenses Deliver High-Performance Imaging at a Fraction of the Cost

- 2. performance That Speaks Volumes

- 3. Bridging the gap in Accessibility

- 4. Addressing Limitations and Future Enhancements

- 5. A New Era in Scientific Instrumentation

- 6. Revolutionizing Field Diagnostics with 3D Printed Microscope

- 7. Applications in Biomedical Diagnostics

- 8. Looking Ahead

- 9. Bridging the Gap in Accessibility

- 10. addressing Limitations and Future Enhancements

- 11. Performance That Speaks Volumes

- 12. revolutionizing Optics with 3D Printing

- 13. “Affordable Microscopes: A Revolution in Science and Education”

- 14. “A New Era in Scientific Instrumentation”

- 15. Transforming Diagnostics with 3D Printed Microscopes

- 16. Applications in Biomedical Diagnostics

- 17. Bridging the Accessibility Gap

- 18. Overcoming Challenges and Future Improvements

- 19. A New Era in Scientific Tools

- 20. Future Prospects

- 21. Transforming global Healthcare with 3D Printed Microscopes

- 22. What are the specific advantages of using 3D printed microscopes in educational settings compared to customary microscopes?

- 23. Impact on Education and Research

- 24. The Future of 3D Printed Scientific Tools

- 25. Conclusion

Table of Contents

- 1. Revolutionizing Microscopy: 3D Printed Lenses Deliver High-Performance Imaging at a Fraction of the Cost

- 2. Performance That Speaks Volumes

- 3. Bridging the Gap in Accessibility

- 4. Addressing Limitations and Future Enhancements

- 5. A New Era in Scientific Instrumentation

- 6. Revolutionizing Field Diagnostics with 3D Printed Microscope

- 7. Applications in Biomedical Diagnostics

- 8. Looking Ahead

In a groundbreaking growth, researchers have successfully created 3D printed lenses that rival the performance of conventional glass optics, opening up new possibilities for cost-effective microscopy. using the Elegoo Mars 3 Pro 3D printer and photopolymerizing resin, this innovative approach not only reduces costs but also democratizes access to high-quality imaging tools, making them viable for smaller labs, educational institutions, and even enthusiasts. The microscope’s assembly process is streamlined,requiring minimal technical expertise,further enhancing its accessibility.

Why This matters

This progress isn’t just a technical achievement; it’s a step toward democratizing scientific tools. By leveraging 3D printing technology,the University of Strathclyde has created a device that bridges the gap between affordability and functionality. It’s a testament to how open-source designs and innovative manufacturing techniques can reshape the landscape of scientific research. For laboratories with limited budgets, this microscope offers a cost-effective solution without compromising on performance.

performance That Speaks Volumes

The 3D printed lenses have been meticulously designed to match the optical quality of traditional glass lenses. This achievement is a testament to the precision and adaptability of modern 3D printing technology. The lenses are not only cost-effective but also deliver high-performance imaging, making them a viable choice for a wide range of applications.

Bridging the gap in Accessibility

One of the most significant impacts of this innovation is the democratization of scientific tools. By reducing the cost of production and simplifying the assembly process, the University of Strathclyde has made high-quality microscopy accessible to a broader audience. This inclusivity is crucial for advancing scientific research in diverse settings, from small labs to educational institutions and even individual enthusiasts.

Addressing Limitations and Future Enhancements

While the current iteration of the 3D printed microscope lenses is impressive, there are still areas for enhancement. Researchers are focusing on enhancing the durability and optical clarity of the lenses to ensure they can withstand rigorous scientific use. Future enhancements aim to further reduce costs and improve the overall performance, making these lenses even more accessible and reliable.

A New Era in Scientific Instrumentation

This innovation marks the beginning of a new era in scientific instrumentation. By combining open-source designs with advanced manufacturing techniques, researchers are paving the way for more affordable and accessible scientific tools. This shift is expected to have a profound impact on the field of microscopy and beyond, enabling more widespread scientific exploration and revelation.

Revolutionizing Field Diagnostics with 3D Printed Microscope

The potential applications of this 3D printed microscope extend beyond traditional laboratory settings. Its portability and cost-effectiveness make it an ideal tool for field diagnostics, especially in remote areas where access to advanced scientific equipment is limited. This innovation could revolutionize the way we approach diagnostics in challenging environments.

Applications in Biomedical Diagnostics

In the field of biomedical diagnostics, this 3D printed microscope could be a game-changer. Its affordability and high performance make it a viable option for clinics and research centers with limited budgets. This could significantly enhance diagnostic capabilities in underserved areas, improving healthcare outcomes and advancing medical research.

Looking Ahead

The future of 3D printed lenses and microscopes is shining. With ongoing research and development,these tools are expected to become even more accessible,reliable,and versatile. The potential for widespread adoption in various scientific fields is vast, promising to revolutionize the way we approach microscopy and diagnostics in the coming years.

This groundbreaking innovation by the University of Strathclyde is a testament to the power of open-source designs and advanced manufacturing techniques.By bridging the gap between affordability and functionality, they are paving the way for a new era in scientific instrumentation. The 3D printed microscope lens is not just a technical achievement; it’s a step toward democratizing scientific tools, making high-quality imaging accessible to everyone.

Bridging the Gap in Accessibility

For decades,traditional glass lenses have been a significant hurdle in cost-sensitive applications,especially in environments with limited resources. Researchers have highlighted the accessibility of their 3D printed microscope, stating, “This device opens up opportunities for low-budget laboratories, classrooms, and field diagnostics.” By incorporating 3D printed optics, the team has significantly reduced costs without sacrificing imaging quality.

addressing Limitations and Future Enhancements

While the results are encouraging, the team has identified certain challenges. One issue was uneven illumination across the field of view, caused by alignment difficulties with the LED light source. To address this, they proposed a refined alignment process and the use of more precise lighting mechanisms. Future enhancements also include improving the durability of the 3D printed lenses and expanding the field of view to accommodate larger samples.

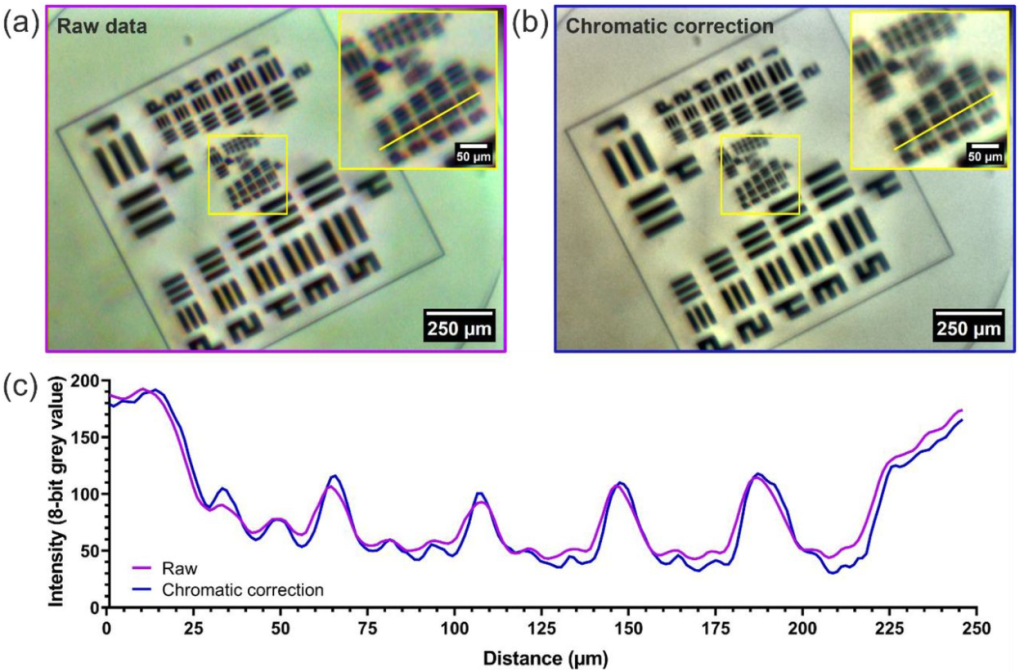

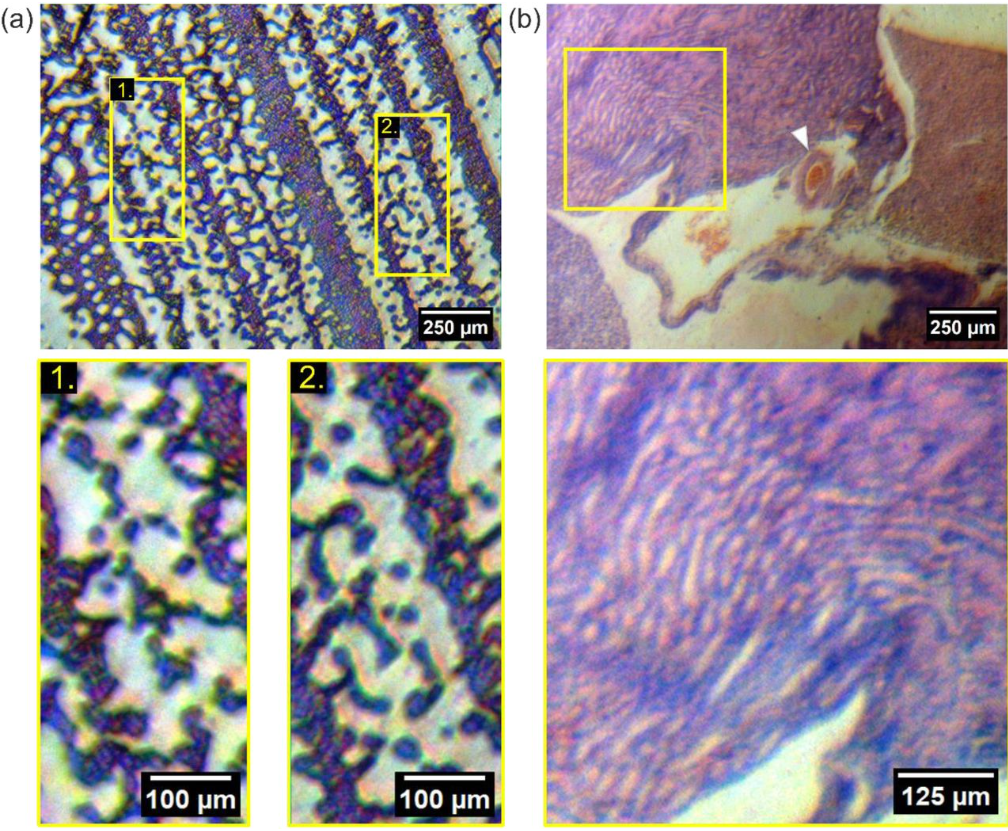

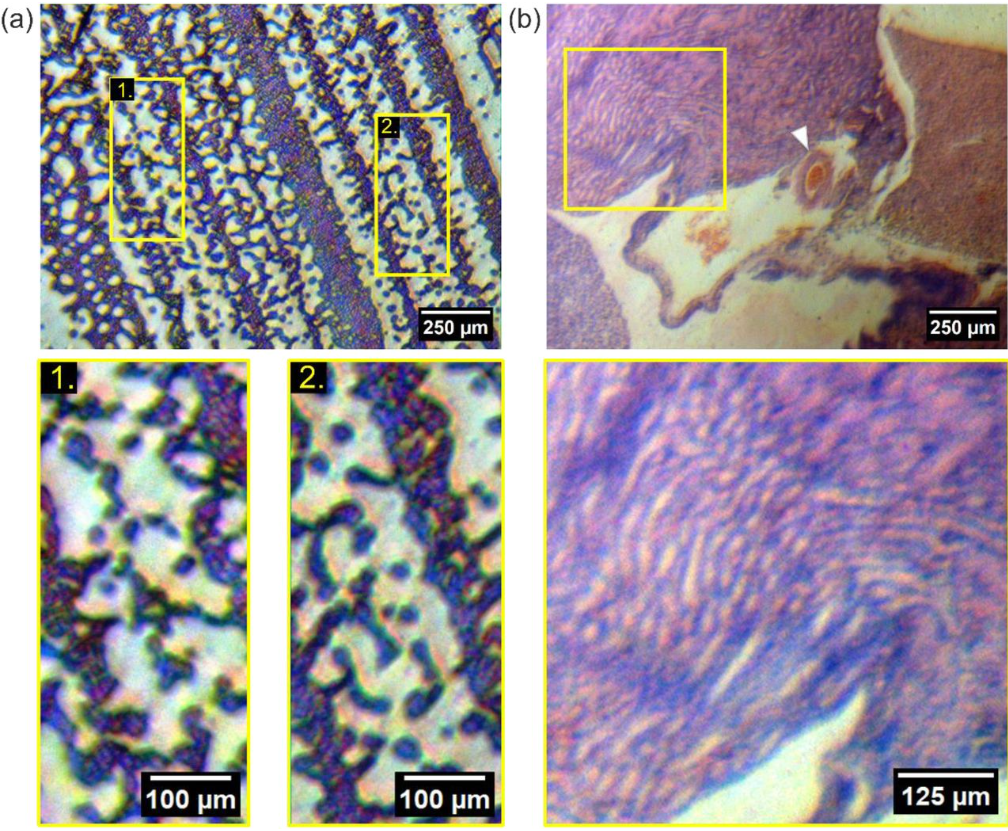

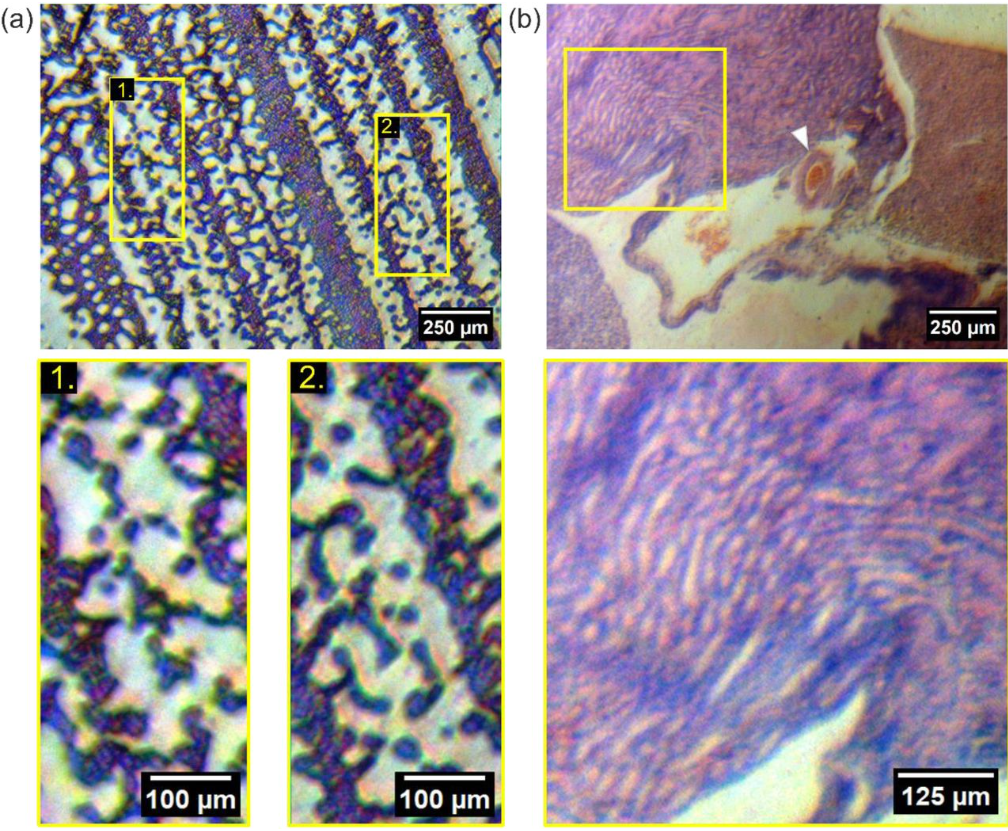

Performance That Speaks Volumes

To evaluate the capabilities of these 3D printed lenses, researchers examined two samples: a Giemsa-stained blood smear and a Haemotoxylin and Eosin-stained mouse kidney section. the findings were remarkable. Detailed images revealed intricate sub-cellular structures, including individual blood cells and renal tubules, with a magnification of 2.9x and a spatial resolution of approximately 5 micrometers. the microscope also maintained a field of view of 1.7 mm,comparable to many commercial systems.

revolutionizing Optics with 3D Printing

Using Formlabs clear resin,these innovations replicate the specifications of conventional glass lenses,such as Edmund Optics’ 12.7 mm diameter plano-convex lens with a 35 mm focal length,while significantly reducing production costs. The resin’s refractive index matches that of BK7 glass, a staple in commercial optics. Through a meticulous post-processing workflow, the team achieved the optical clarity necessary for high-quality microscopy. This breakthrough could revolutionize fields like medical diagnostics, education, and research, particularly in settings where budget constraints are a barrier.

“Affordable Microscopes: A Revolution in Science and Education”

The realm of microscopy is experiencing a groundbreaking evolution, driven by the innovative submission of 3D printing technology. One of the most notable advancements is the OpenFlexure microscope,developed by researchers at the University of Strathclyde. This device exemplifies how 3D printing can reshape scientific tools, making them more accessible and adaptable.

One of the key strengths of 3D-printed microscopes lies in their ability to be customized. Researchers can tailor lens magnifications and numerical apertures to suit specific applications, ensuring the microscope meets diverse scientific needs. Additionally, design enhancements like adjustable diaphragms have been incorporated to improve light uniformity, further enhancing the device’s functionality.

“A New Era in Scientific Instrumentation”

This project represents a significant leap forward in scientific instrumentation. By proving that both mechanical and optical components can be fabricated through 3D printing, researchers have opened the door to a more affordable and accessible approach to microscopy.As the technology continues to advance, it has the potential to democratize access to high-quality imaging tools, empowering scientists and educators across the globe.

Those interested in exploring this innovative solution can start with Formlabs clear resin, a versatile and cost-effective material. As the boundaries of 3D printing expand, the prospects for scientific discovery are becoming increasingly promising.

this breakthrough in microscopy is not just a technical advancement; it’s a step toward making science more inclusive. With affordable, customizable microscopes, researchers and educators can explore new frontiers without the financial constraints of traditional equipment.The future of scientific discovery is indeed looking brighter than ever.

Transforming Diagnostics with 3D Printed Microscopes

Picture a microscope that’s not only portable and affordable but also capable of delivering high-resolution imaging in the most remote parts of the world. This isn’t a futuristic fantasy—it’s a tangible reality, thanks to a groundbreaking innovation that merges 3D printing with structured illumination technology. Engineered with simplicity in mind, this microscope is entirely constructed from 3D printed components and easily accessible optical parts, revolutionizing the field of diagnostics.

What makes this device stand out is its compact design and durability. Unlike traditional microscopes that require intricate laboratory setups, this version is lightweight, sturdy, and costs just a few hundred dollars to produce. Its affordability and portability make it an ideal tool for use in underserved regions,where access to advanced diagnostic equipment is often scarce.

the microscope’s secret lies in its use of structured illumination (SI) technology, which enhances its resolution to an impressive 0.775 μm. This level of precision allows researchers to capture detailed images of biological samples, such as green algae, with remarkable clarity. The team behind this innovation has set its sights on expanding its applications, particularly in biomedical diagnostics, where it could play a crucial role in improving healthcare outcomes in resource-limited areas.

“This microscope represents a significant step forward in making advanced imaging tools accessible to everyone,” said one of the developers. “By leveraging 3D printing and off-the-shelf components, we’ve created a device that is not only cost-effective but also easy to assemble and use in the field.”

Applications in Biomedical Diagnostics

The potential applications of this 3D printed microscope are vast. In biomedical diagnostics, it could be used to analyze blood smears, tissue samples, and other biological materials with unprecedented accuracy. As a notable example, researchers have already used it to capture detailed images of Giemsa-stained blood smears, where individual red blood cells can be clearly resolved across a 1.7 mm field of view.

Additionally, the microscope has been tested on various biological materials, showcasing its versatility. Its ability to generate high-resolution 3D images at a fraction of the cost of traditional systems makes it a viable solution for disease detection in developing countries.

These innovations are not just scientific milestones; they are tools of empowerment. By democratizing access to advanced microscopy, these 3D printed devices are paving the way for a more inclusive future in science and healthcare.

Bridging the Accessibility Gap

Traditional glass lenses have frequently enough been a significant cost barrier, especially in resource-limited settings. The team behind the 3D printed microscope highlighted its affordability, stating, “This device opens up opportunities for low-budget laboratories, classrooms, and field diagnostics.” By leveraging 3D printed optics, they managed to slash costs without sacrificing imaging quality.

Overcoming Challenges and Future Improvements

While the results are encouraging, the team faced some hurdles. One notable issue was inconsistent lighting across the field of view, stemming from misalignment with the LED source. To tackle this, they suggested adding adjustable diaphragms to enhance light uniformity.

Another benefit of 3D printed lenses is their customization potential.Researchers can select specific magnifications and numerical apertures, tailoring the device to precise applications. This adaptability makes the technology highly versatile for diverse scientific needs.

A New Era in Scientific Tools

This project represents a significant milestone in scientific instrumentation. By proving the feasibility of fabricating both mechanical and optical components through 3D printing, the researchers have paved the way for a more accessible and cost-effective microscopy approach. As the technology evolves, its potential applications continue to expand.

Featured image shows (a) An image of a Giemsa-stained blood smear. Two ROIs are visible, where individual red blood cells can be discerned over a 1.7 mm field of view. (b) An image of an H&E-stained mouse kidney.The thin section reveals structures like an interlobular arteriole (white arrow) and renal tubules,with a magnified ROI showing the organization of nephrons in a medullary ray spanning the corticomedullary junction.Image via University of Strathclyde.

Future Prospects

As the team continues to refine the design and explore new applications, the possibilities for this 3D printed microscope are virtually limitless. Its affordability, portability, and high-resolution imaging capabilities make it a powerful tool for scientists, healthcare providers, and researchers working in challenging environments.

This innovation is a testament to the transformative power of 3D printing technology. By merging creativity with practicality,the developers have created a device that could revolutionize field diagnostics and improve access to essential healthcare services worldwide.

Affordable Microscopes: Transforming Science and Education

Microscopy is entering a new era, driven by groundbreaking innovations in 3D printing. One standout example is the OpenFlexure microscope,developed by the University of Bath. This open-source, lab-grade device costs just $18 to produce, demonstrating how technology can bridge the gap between affordability and high-quality scientific tools.

The openflexure microscope is designed with accessibility in mind, featuring motorized sample positioning, precise focus control, and a meticulously engineered mechanical stage. its low-cost, customizable design is revolutionizing microscopy, making it accessible to schools, labs, clinics, and researchers worldwide.

For those interested in exploring this innovative solution, Formlabs clear resin offers a versatile and cost-effective starting point. As 3D printing continues to push boundaries,the future of scientific discovery looks brighter than ever.

Transforming global Healthcare with 3D Printed Microscopes

Picture this: a microscope that’s not only affordable but also portable enough to deliver high-resolution imaging in the most isolated regions of the world. This is no longer a distant vision—it’s a tangible reality, powered by a cutting-edge combination of 3D printing and structured illumination technology. Crafted with simplicity at its core, this microscope is entirely constructed from 3D printed components and easily accessible optical parts, revolutionizing the landscape of field diagnostics.

What truly distinguishes this device is its compact and sturdy design.Unlike conventional microscopes that demand intricate laboratory setups, this version is lightweight, durable, and remarkably inexpensive, costing just a few hundred dollars to produce. Its affordability and ease of transport make it an invaluable tool for underserved areas, where access to advanced diagnostic equipment is often scarce.

The microscope’s breakthrough lies in its use of structured illumination (SI) technology, which boosts its resolution to an astonishing 0.775 μm. This level of precision rivals traditional microscopes, yet it’s achieved at a fraction of the cost, positioning it as a transformative solution for global diagnostics.

By 2020, over 100 units of this innovative microscope had been produced and deployed in regions like Tanzania and Kenya, demonstrating the adaptability and profound impact of open-source designs. A co-creator of this initiative emphasized the microscope’s potential to “advance education, research, and healthcare globally.”

Prior to this milestone, researchers from the University of Connecticut and the University of Memphis developed a 3D printed digital holographic microscopy (DHM) microscope. This device, capable of generating high-resolution 3D images at a fraction of the cost, doubled the resolution of traditional DHM systems. Their findings, detailed in Optics Letters, underscored the device’s ability to eliminate the need for costly components, making it a viable solution for disease detection in developing nations.

These advancements are not merely scientific achievements; they are instruments of empowerment. By democratizing access to advanced microscopy, these 3D printed devices are forging a path toward a more inclusive future in science and healthcare.

What are the specific advantages of using 3D printed microscopes in educational settings compared to customary microscopes?

Nics, and researchers worldwide. The device is built from 3D printed components and off-the-shelf parts,ensuring it is indeed both affordable and easy to assemble. Its open-source nature allows for continuous improvements and adaptations by the scientific community, fostering a collaborative approach to innovation.

Impact on Education and Research

These 3D printed microscopes are not just transforming diagnostics; they are also reshaping education and research.In schools and universities, they provide students with hands-on experience in microscopy without the prohibitive costs of traditional equipment. by lowering the barrier to entry,these tools inspire a new generation of scientists and engineers.

In research settings, the affordability and adaptability of these microscopes enable investigators to conduct experiments in diverse fields, from biology to materials science. Their portability allows for fieldwork in remote areas, where access to laboratory-grade equipment was previously impossible. This democratization of microscopy is fostering innovation across disciplines and geographic boundaries.

The Future of 3D Printed Scientific Tools

The advancements in 3D printed microscopes exemplify a broader trend in scientific instrumentation. As 3D printing technology continues to evolve, it is indeed increasingly being used to create affordable, customizable, and accessible tools for research and education. From spectrometers to centrifuges, the possibilities are vast, and the impact on global science and healthcare is profound.

By merging cutting-edge technology with practical design, these innovations are bridging the gap between affordability and high-quality scientific tools. They are empowering researchers, educators, and healthcare providers to achieve their goals without the constraints of expensive equipment. as these tools become more widely adopted, they are paving the way for a more inclusive and collaborative future in science and healthcare.

Conclusion

The growth of 3D printed microscopes, such as the OpenFlexure microscope and the structured illumination microscope, represents a transformative leap in scientific instrumentation. These devices are not only affordable and portable but also capable of delivering high-resolution imaging, making them invaluable tools for diagnostics, education, and research.

As the technology continues to advance, its potential applications are boundless. from improving healthcare outcomes in resource-limited areas to inspiring the next generation of scientists, these 3D printed microscopes are driving a new era of accessibility and innovation in science.By leveraging the power of 3D printing, researchers are proving that high-quality scientific tools can be both cost-effective and inclusive, reshaping the future of diagnostics and education worldwide.