2023-06-01 15:13:02

You might not even like the Apple Watch and prefer the style of more traditional watches, but one thing is impossible to deny: the Apple smartwatch has, by far, one of the easiest and most practical bracelet changing systems that exist, the kind that makes you stop and think: “Why? that no one has ever done this before?”

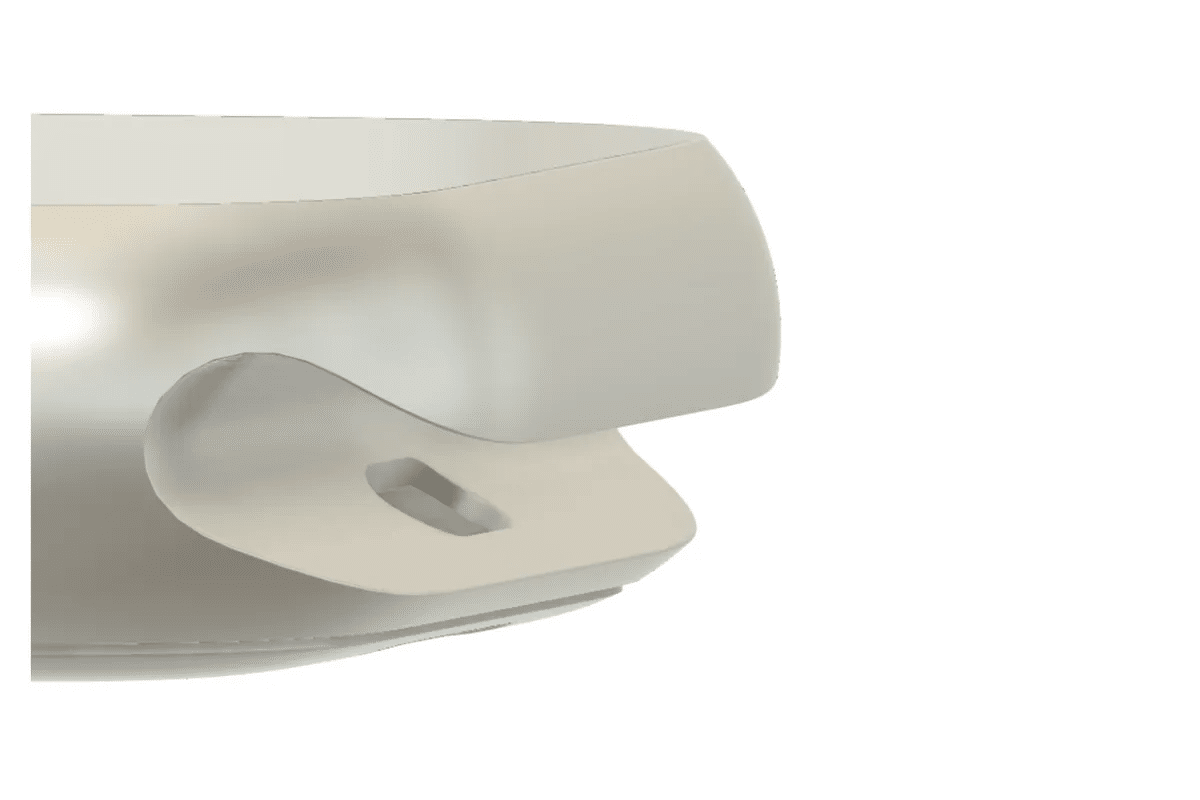

To remove the bracelet from an Apple watch, it’s extremely simple: just press one of the buttons located at the bottom of the garment and drag one of the ends of the bracelet to the side. To fit a bracelet back, it’s even easier: just insert the tip of the accessory into one of the watch’s sockets and drag it to the side until you hear a click… very satisfying. ????

What a lot of people don’t know is that, for this process to become as simple as that, Apple had to spend a good few million dollars to develop the mechanism for fitting the Watch bracelets, which does not require the use of any watchmaking tool. . A report published this week by The Vergehowever, tells this story blow by blow.

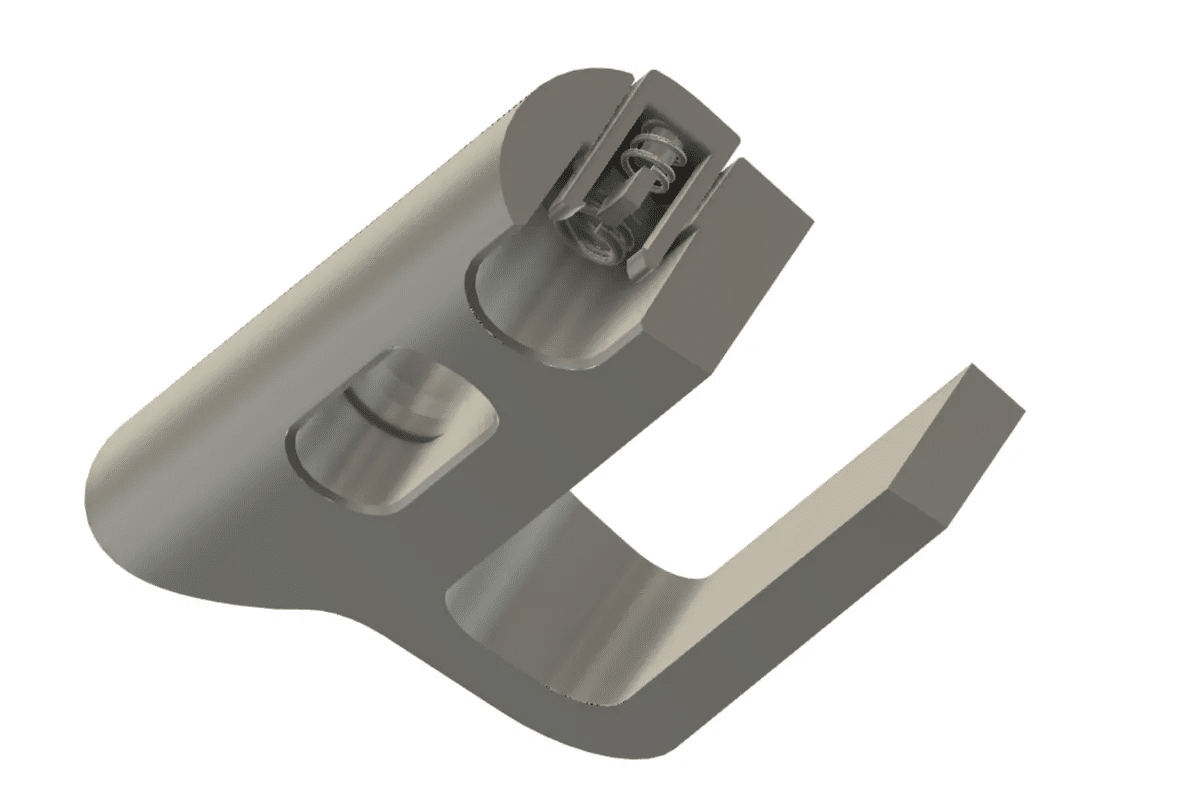

If we look closely at one of its ends, we can see that the mechanism for fitting the Apple Watch bracelets is actually made up of three different buttons, two of which are so precisely cut that the Cupertino giant, according to the report, had to reconsider its entire watch-making process.

The first button comes into action as soon as the user begins to insert the tip of the bracelet into the Apple Watch socket and serves to press the second button following being pushed into a cavity inside the bracelet itself. As soon as the second button lines up with either of those two cutouts located on the watch’s notches, the bracelet is finally secured — which is signaled by that characteristic click.

The process to remove the bracelet is very similar. When the user presses one of those two buttons at the bottom of the wearablethe second button is pushed out of the socket that secured it to the watch, allowing the wearer to pull the bracelet to the side and remove it.

That way, it might not even seem like such a complex mechanism. However, in order for it to work as expected, each button needs to be cut with impressive precision. According to The Vergeto make its bracelet-changing system possible, Apple has invested in hundreds of extremely precise Swiss machines that cost nothing less than $2 million each(!) just to cut these components, nothing more.

As noted by the report, a strand of hair is usually 70 microns (or micrometers, identified by the symbol μm) thick, and most of these machines can cut parts with an accuracy of 50μm. The model purchased by Apple for its production line, however, manages to operate with an accuracy of approximately 5μm.

According to former engineers heard by the vehicle, the biggest buyer of this type of tool before the arrival of the Apple Watch was the luxury Rolex. In one fell swoop, Apple bought more units of this machine than any other watch maker had ever bought.

Contrary to what some may imagine, this system was not the idea of the former head of Apple design, Jony Ive, who wanted to use magnets to hold the bracelets in place. All this investment, however, paid off, as the market for watch straps is now worth something in the home of $1 billion.

The full report of The Verge can be viewed in full on this page. Very interesting, isn’t it?

Apple Watch Ultra

Apple Watch Series 8

Apple Watch SE

TRANSPARENCY NOTE: The MacMagazine You receive a small commission from sales completed through links in this post, but you, as a consumer, pay nothing more for products you purchase through our affiliate links.

1685684105

#Report #dissects #operation #Apple #Watch #bracelets