“Did you know that our optical mirror was used in the high-resolution camera ‘LUTI’ of Korea’s first lunar probe, Danuri?”

The Korea Research Institute of Standards and Science, Korea’s representative national measurement standard organization. Yang Ho-soon, senior researcher of the Space Optics Team, whom we met here, said, “The optical mirrors made by the Standards Institute played a part in the development of our space field.”

Luti, a high-resolution camera for lunar exploration, is a device that took pictures of the lunar surface and the earth, which was unveiled in the new year. Both the primary and secondary mirrors, key parts used in Lutie, were produced by the space optics team of the Korea Standards Institute.

Senior researcher Yang told reporters that these optical mirrors are special. Luti’s main mission is to select a lunar lander landing site. Like the human eye, it must be able to accurately recognize objects and distances.

Principal Researcher Yang explained, “Like the human eye, Luti has a pair of optical mirrors,” and “through this, in-depth information can be obtained.”

It is also meaningful to make an optical mirror that can withstand the harsh space environment with pure Korean technology.” Senior researcher Yang said, “We went through an environmental test in advance of dozens of cycles at minus 15 to 55 degrees Celsius, and made it able to withstand extreme vibration during launch.”

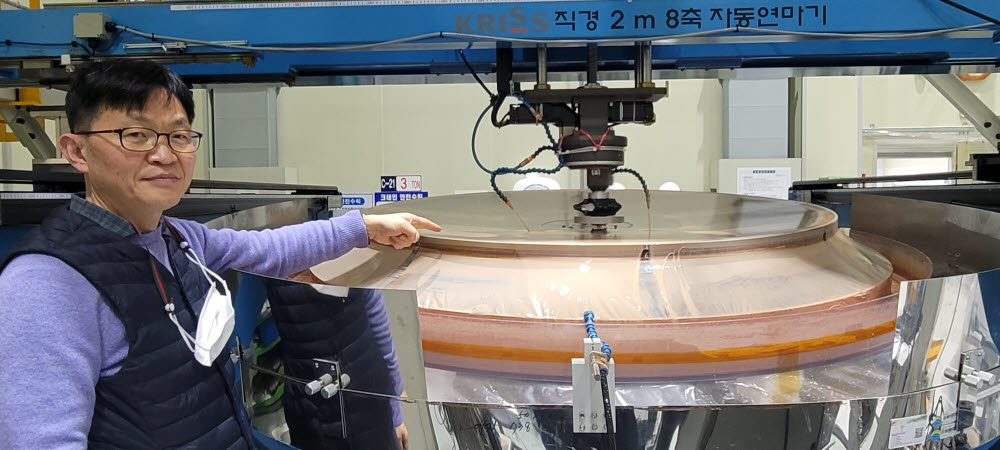

With the guidance of Senior Researcher Yang and Senior Researcher Yoonwoo Lee, we were able to see the large-scale optical processing room within the Standard Research Institute. A new optical mirror was being born in a space the size of an indoor playground with high ceilings. It was possible to see the production of a 1.6m ground optical mirror.

Ocher-colored abrasive liquid was sprayed onto the fixed mirror, and a small circular device moved over it. Together, senior researcher Han Yang explained, “We are in the process of shaving the aspheric structure that gradually flattens from the center to the periphery very little.”

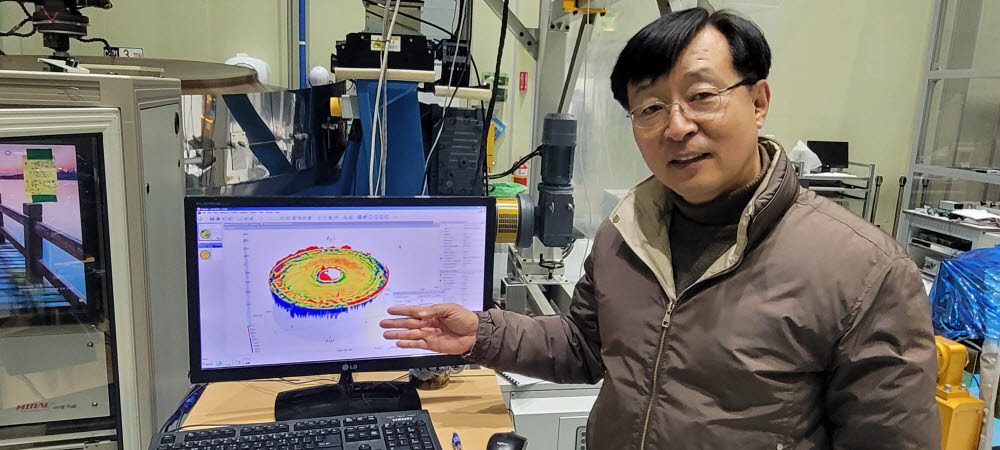

The current state of the mirror was displayed on the computer in front of the grinder. The areas marked in red were said to require more polishing. Principal researcher Lee said, “It is processed with nanometer (nm) precision to the extent that you cannot feel the difference with the naked eye.” He continued, “We will be able to prove the capabilities of the space optics team at the Standard Research Institute once more by completing this mirror at the end of this month.”

The space optics team has made numerous achievements so far. The 600mm optical mirror used in the next-generation medium-sized satellite is also a standard work. It also has the technology to make 1m-class mirrors. It is the level of technology that is second only to the United States. In addition to the 1.6m optical mirror for ground use, which the reporter was guided by, a 1.2m space mirror is also being made. In the near future, we plan to challenge the development of a 2m level optical mirror. The one used in the Hubble Telescope in the past is 2.4 m. If you look at the ground with a 2m optical mirror, you can discern the size of a soccer ball.

Principal researcher Lee said, “Optical mirrors are important not only in the space field but also in the defense field, so China and Japan are already developing satellite cameras using 2m mirrors.” .

Reporter Youngjun Kim [email protected]