In terms of advanced wafer technology, American manufacturers are also behind TSMC and Samsung. These two mass-produced or regarding to be mass-produced 7nm, 5nm and 3nm are far ahead. However, the United States has more plans, not necessarily in advanced The technology surpasses them, and even prepares to go retrograde, resurrecting the 90nm process, and the performance of the manufactured wafer is 50 times that of the 7nm wafer.

U.S. fab SkyWater has announced that it has received further funding from DARPA, a subsidiary of the U.S. Department of Defense, which will give $27 million to promote the development of a 90nm strategic radiation-hardened (RH90) FDSOI technology platform, with a total investment plan of up to $170 million.

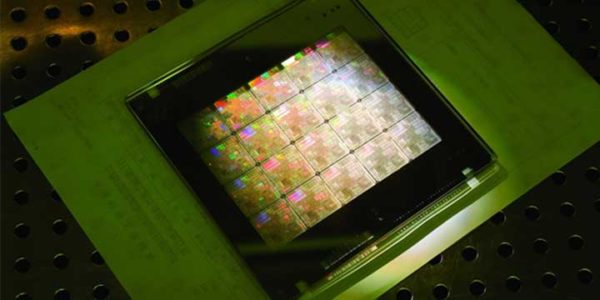

Compared with semiconductor companies such as TSMC, Samsung, and Intel, SkyWater is not only small in scale, but also has less qualifications. It was established in 2017. The fab is mainly derived from the wafer manufacturing department of Cypress Semiconductor. The technology is not advanced, and the main production 130nm and 90nm, some advanced wafers only reach the 65nm level.

However, they were favored by DARPA in the United States, and began to participate in the latter’s ERI Electronics Revival Program not long following its establishment, which invested 1.5 billion US dollars in five years to promote the development of the US semiconductor industry.

In the ERI plan, SkyWater does not pursue advanced technology with stronger technology but more expensive, but uses 90nm process to manufacture 3D SoC wafers, and achieves stronger performance by integrating materials such as resistive RAM and carbon nanotubes, and the performance can reach 7nm wafers. 50 times the circle.

Of course, these technologies have not yet achieved a complete breakthrough. After all, such an approach has not been done before. Once successful, it may be a new technology that changes the rules of the semiconductor industry.

Further reading: