2023-09-04 14:18:47

3D printing 50,000 nozzles in one month: that is the largest order that Tenco DDM has received so far since it made the transition from 3D printing of prototypes to real additive manufacturing of end parts.

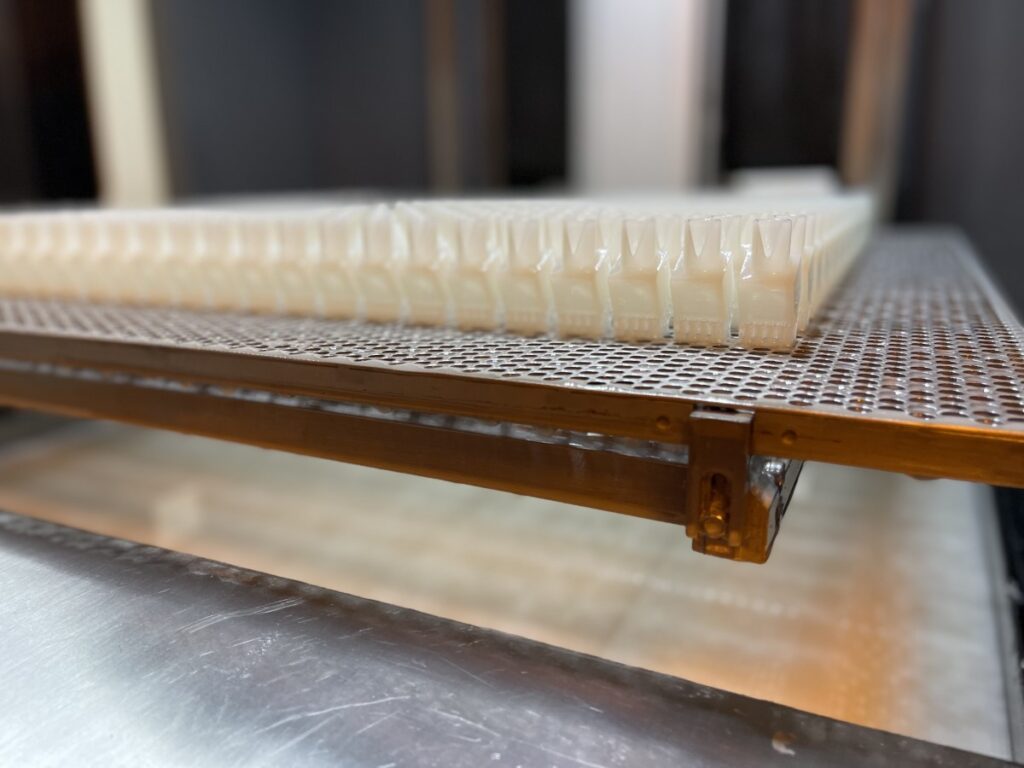

When Frank Nelissen, head of sales at Tenco DDM, receives a call from Henkel asking whether they can 3D print 50,000 nozzles in the short term, he senses the rush on the other side of the line. A justified suspicion, it soon turns out. An automotive customer of the adhesive manufacturer needs the nozzles for bonding car windows. The robot that applies the adhesive takes a new nozzle for each windshield. Because it is a relatively small nozzle, Tenco can deliver 50,000 pieces in a month. “We adapted the design and started printing on two DLP machines. One build took 23 hours; we had exactly one hour to prepare the next build.” 1,000 nozzles might be printed per build. Simultaneously with the start of additive production, Tenco DDM started developing an injection mold. Local. The nozzles are now an injection molded product once more. This assignment illustrates the turnaround that Tenco DDM has made in recent years. From a 3D printing company for prototypes to a company that provides solutions. These can be industrial applications with additive manufacturing, says business manager Tom Castermans. But it can also ultimately be an injection molded product. Or a CNC machined product. “We focus on customer demand and no longer on technology,” adds Frank Nelissen.

We focus on customer demand and no longer on technology

Deploy AM to production faster

This change of course started a few years ago. Until then, the emphasis was on 3D printing prototypes. “But the attention quickly disappears when you say you are a 3D printing company,” notes Frank Nelissen. Most companies have hardly any idea what industrial additive manufacturing can do. They hardly know anything regarding techniques other than FDM and the materials for this. As a result, there are no production orders; no repeat orders. By positioning itself differently, Tenco DDM is now winning it. “We see ourselves as a plastics processing company. This positioning makes it easier for the customer to understand what we do. If we then put down a piece, the customer sees the solution. It no longer matters how we achieve that solution.” By investing in design knowledge, the Genker company fills the knowledge gap in the market. With this approach you can persuade companies more quickly to make certain parts of their production with additive manufacturing. Aspects such as the series size, lead time and complexity then determine whether a part is printed or not Tenco DDM still opts for injection molding or milling. The 50,000 nozzles for Henkel are a good example. “By printing, we buy time to make a mold. Time that is important because otherwise production at the end customer will come to a standstill.” In other situations, a mold is never made, for example because the customer wants to remain flexible in terms of design adjustments; or that the series turn out to be smaller following all.

AM on an industrial scale

Additive manufacturing on an industrial scale is therefore certainly possible. Tenco DDM prints with SLA and DLP printers. The liquid polymers for this, Tenco works with Loctite (Henkel) materials, have undergone enormous development. As a result, the accuracies required by a production environment (standard 0.1 mm, 0.05 mm is also possible) are achievable, as is the quality. Tom Castermans: “We print with SLA and DLP in injection molding quality.” The improved possibilities for the finishing of the pieces is a second reason why the step to additive manufacturing can be made. Tenco DDM applies EMC shieldings to machine covers, lacquer coatings to parts or special coatings for optical components in its own workshop. Tenco DDM has optimized post processing. “Instead of cleaning a lot, we can use the new materials with just one cleaning and then the piece is clean.” Cleaning is semi-automated because a pump pumps the liquid through the cleaning container.

Internal processes have changed

“In addition, one of the main conditions was that we dared to let go of customers,” says Tom Castermans. He mainly means the large design agencies, for which the Genker company used to do a lot of 3D printing. This has created space for industrial customers. In addition, he assumes risk in order to gain customer trust. “If a customer is in doubt, we print 5 pieces and only the rest when the customer is convinced. Once the trust is there, things move quickly.” The repeat orders mean that Tenco DDM can plan the work better and use the capacity more efficiently. The step from copier – as Frank Nelissen describes the former activities of Tenco DDM – to plastics processor did have some internal consequences. Checks, measurement reports, releases: these are matters that are now dealt with daily in the work. But also much more intensive consultation with customers. Frank Nelissen and two colleagues are responsible for account management. Frank Nelissen: “I think it’s great that some 3D printing companies say that you have a quotation within 20 minutes and the product within 24 hours. If you first look at what the customer needs, you cannot make a quote within 20 minutes.”

Arguments for additive manufacturing

Thanks to this approach, Frank Nelissen conducts a completely different discussion with customers than before. As he pointed out, the focus is on the solution to the problem, not the technology. Tom: “It’s nice when a customer says how you make the part is your problem. Then we can start steering in the direction of the best solution. That can be milling, injection molding or additive manufacturing.” There is no general tipping point that indicates when additive manufacturing is more interesting than injection molding. Sometimes products are still in the development phase for a long time. Then 3D printing of small batches can be more attractive. In another application, sales may not yet be stable enough to invest in an injection mold. Tom Castermans often sees this in companies that are working with VR applications; or with body-mounted sensors. And then there is the urgency, as with the Henkel order. If parts are needed quickly, additive manufacturing is the obvious choice. He does not mention complexity, a frequently heard reason. Tom Castermans: “In the past you often heard that you have to 3D print what you cannot make otherwise, because the parts are too complex. To be honest: we don’t come across those pieces very often. I see few designs that we print that you cannot mill or injection mold.” It is the other reasons that are now the deciding factor in choosing additive manufacturing. Often the lead time. At Henkel there was the risk of production downtime at the end customer. Then there is no choice; then the strength of the additive manufacturing technology comes out best.

URL Copied

1693967076

#nozzles #Delivery #time #month