2024-03-20 05:00:02

As plastic waste proliferates in landfills and aquatic environments, the development of effective recycling and revaluation processes for these materials, which are omnipresent in our daily lives, is essential. In an article published in Angewandte Chemie International Edition, CNRS chemists present a one-step route that uses commercial catalysts to upgrade rubber waste into high value-added products for the chemical industry.

The plastics industry has experienced spectacular development over the last century, going from 1.5 million tonnes produced per year in 1950 to more than 430 in 2022. This amounts to an average increase of 8.5% per year, unprecedented for any other family of materials. And for good reason: these light, resistant and very versatile materials have gradually replaced wood and other natural materials, glass or metals in a number of applications. But this development is not without consequences and the observation is no longer in doubt: plastic waste scattered in the environment without degrading represents a real threat to ecosystems and populations. Several avenues are therefore being studied, some already well established, to collect, recover, sort and recycle this waste.

Plastics are mainly made up of polymers, long macromolecular chains obtained by the reaction between smaller molecules: monomers. Ideally, the recycling of plastic waste should make it possible to return to the initial material – the monomer – to produce new plastics, or even other chemicals or reaction intermediates with high added value. Chemical recycling by depolymerization of polymers into monomers, however, faces a major obstacle: the low cost of virgin monomers from petrochemicals.

Polymer upcycling is another promising approach that transforms polymers from plastic waste into molecules with higher added value. Depending on the situation, this upcycling scheme can offer an energetically and sometimes ecologically more favorable alternative than traditional chemical recycling by depolymerization. To be economically viable, however, this approach must produce compounds more valuable than virgin monomers and polymers.

In this context, chemists from the Paris Chemistry Research Institute (CNRS/Chimie ParisTech/PSL) were interested in the upcycling of nitrile-butadiene rubber (NBR) waste. This widely used synthetic rubber is a copolymer composed of two different monomers: acrylonitrile (A) and butadiene (B). The proportions of A and B allow you to vary the properties of this rubber resistant to oil, fuel and other chemicals as desired.

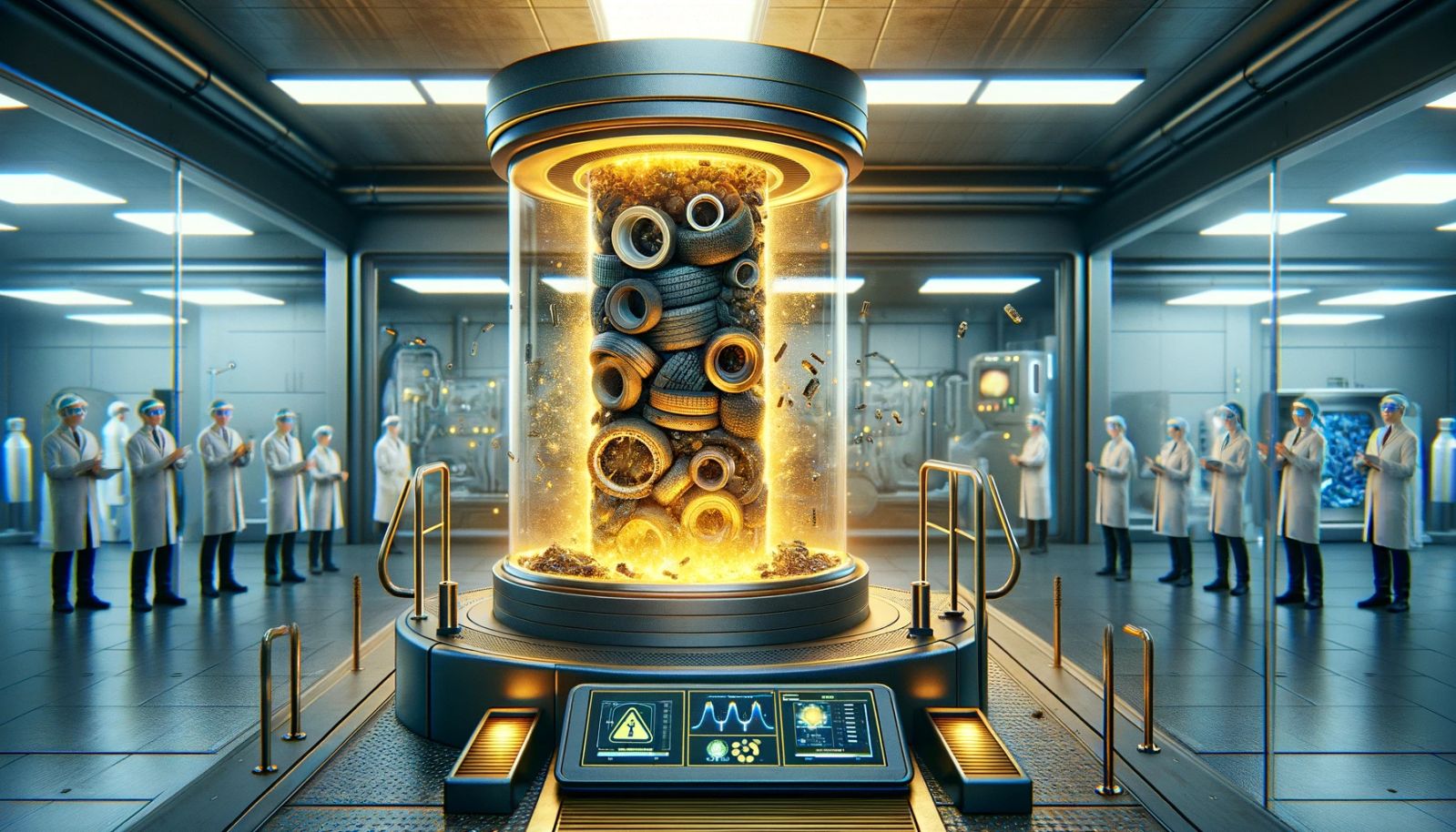

A one-step process for decomposing NBR rubber waste in the presence of commercial catalysts (ruthenium and magnesium) makes it possible to generate high value-added products such as unsaturated polyesters.

© Christophe Thomas

NBR is most often used where high oil resistance is required, such as in automotive gaskets and joints or pipes for transporting petroleum products. NBR is also used in the textile field, where its application to woven and non-woven fabrics improves the finish and waterproofing properties. The end of life of NBR products depends on the product itself. Typically, they are thrown into a landfill where they will eventually degrade and release chemicals into the environment.

The team of scientists proposes a much more ecological alternative which uses several commercial catalysts based on ruthenium and magnesium and allows the valorization of nitrile-butadiene rubber waste in a single step. In this process, small directly usable nitrile molecules are formed as well as oligomers (very short chains) of butadiene converted into difunctional acids. These react with biosourced alcohols to form unsaturated polyesters. This very promising method therefore makes it possible to convert rubber waste under mild conditions into a new polymer whose structure and properties are highly adjustable.

This work, published in the journal Angewandte Chemie International Edition, represents an interesting strategy for the efficient and sustainable development of new high-performance eco-materials which is part of a circular economy of plastic materials.

Editor: AVR

Reference:

A New Life For Nitrile-Butadiene Rubber: Co-Harnessing Metathesis And Condensation For Reincorporation Into Bio-Based Materials

Jakhongir Bekmirzaev, Malaury Simon, Sara D’Aniello, Mina Mazzeo, Sander J. Cohen-Janes, Robert T. Mathers, Régis M. Gauvin & Christophe M. Thomas.

Applied Chemistry International Edition 2024

1710912112

#Transform #rubber #waste #high #valueadded #products